The alternative oil cooler

#21

It was the 1/2" bsp to AN10 adaptors that I drilled out as they had the smallest inner diameter of anything.

My cooler is a full width Setrab 16 row. It's mounted very low, the hoses too so that no oil can drain back to the sump when the engine's not running. It does mean the lower part of the cooler might not get much air flow though.

My cooler is a full width Setrab 16 row. It's mounted very low, the hoses too so that no oil can drain back to the sump when the engine's not running. It does mean the lower part of the cooler might not get much air flow though.

#22

Thread Starter

Well im gradually getting there in regards to the oil cooler.

Oil cooler is now bolted up and fan attached for the cooling. Im abit limited by my coolers 1/2 bsp fittings and drilling them wider would risk swarf getting inside the cooler.

I have deleted the OEM oil water heat exchange which enables me to get the sandwich plate with higher temp thermostat fitted and then i have my oil pressure sensor fitted into another sandwich plate.

I have made up some push fit hoses using some old fittings and hose i had from another job and with the aid of a heat gun and a big vice managed for once to get the fittings over the barbs all the way. The hose diameter is 13mm with 1/2 bsp fittings on the end, it works surprisingly well at the moment with minimal pressure loss.

I have contacted a hydraulic hose company who have priced up the hoses made in stainless steel braided PTFE with a very high burst pressure so over engineered for what i want but will be piece of mind.

Can i just say that if at all possibly based on my experience i would avoid AN fittings and go for BSP any day of the week. Steel coned BSP fittings work again and again but some aluminium AN fittings always seem to leak. Oh and loctite 577 sealant is great at sealing pipe threads on hydraulic systems, it has never once let me down.

Oil cooler is now bolted up and fan attached for the cooling. Im abit limited by my coolers 1/2 bsp fittings and drilling them wider would risk swarf getting inside the cooler.

I have deleted the OEM oil water heat exchange which enables me to get the sandwich plate with higher temp thermostat fitted and then i have my oil pressure sensor fitted into another sandwich plate.

I have made up some push fit hoses using some old fittings and hose i had from another job and with the aid of a heat gun and a big vice managed for once to get the fittings over the barbs all the way. The hose diameter is 13mm with 1/2 bsp fittings on the end, it works surprisingly well at the moment with minimal pressure loss.

I have contacted a hydraulic hose company who have priced up the hoses made in stainless steel braided PTFE with a very high burst pressure so over engineered for what i want but will be piece of mind.

Can i just say that if at all possibly based on my experience i would avoid AN fittings and go for BSP any day of the week. Steel coned BSP fittings work again and again but some aluminium AN fittings always seem to leak. Oh and loctite 577 sealant is great at sealing pipe threads on hydraulic systems, it has never once let me down.

#23

I can't say I've had any issue with AN fittings. I installed an oil cooler last year and after seeing placement when the bumper was put back on, I ended up making a duct for it to get the most air it can through it. I don't have my oil temp sensor installed yet as I was waiting on the Canton pan to come out so I could just install it there. Now I'm just trying to finish other projects.

I went with a 200F Mocal thermostat and I am curious to see what my oil temps are.

I went with a 200F Mocal thermostat and I am curious to see what my oil temps are.

#24

Thread Starter

I can't say I've had any issue with AN fittings. I installed an oil cooler last year and after seeing placement when the bumper was put back on, I ended up making a duct for it to get the most air it can through it. I don't have my oil temp sensor installed yet as I was waiting on the Canton pan to come out so I could just install it there. Now I'm just trying to finish other projects.

I went with a 200F Mocal thermostat and I am curious to see what my oil temps are.

I went with a 200F Mocal thermostat and I am curious to see what my oil temps are.

Look into getting a proper oil cooler fan, mocal state on there website that only a 5th of air flow actually gets pushed through a cooler, the rest avoids it and goes elsewhere. If you get a fan your forcing the air through the core and getting the most out of the cooling. I have mine on a switch which i will probably only use on trackdays.

#25

A fan would serve no purpose compared to that when moving forward.

A proper duct is a much better solution. In addition, when the car's cooling fans come on at lower speeds, it also pulls through the oil cooler.

A proper duct is a much better solution. In addition, when the car's cooling fans come on at lower speeds, it also pulls through the oil cooler.

#26

Thread Starter

As for the oil temperatures, im running a small 115mm 19 row cooler which is half the width of what i think your running and i know overcooling can be a problem. Most thermostatic plates dont work like say a coolant thermostat and they allow oil through the cooler all the time even when its below the thermostats temperature. I have read alot of people moaning about the mocal thermostatic plate not working as they would of wanted. You need to get temperature of 100c every now and then just to burn of the moisture and other crap that collects in the oil.

#27

Originally Posted by yamahaSHO' timestamp='1403897729' post='23220988

A fan would serve no purpose compared to that when moving forward.

A proper duct is a much better solution. In addition, when the car's cooling fans come on at lower speeds, it also pulls through the oil cooler.

A proper duct is a much better solution. In addition, when the car's cooling fans come on at lower speeds, it also pulls through the oil cooler.

With a pull fan configuration you are forcing air through the core of the cooler. The SPAL fan i use moves 240 CFM and is excellent and with the fan on the switch i can choose for additional cooling based on the oil temperature. Its like having the ability to change the size of the cooler based on your driving style. Saying that thou your duct does look good and it probably makes a noticeable difference.

As for the oil temperatures, im running a small 115mm 19 row cooler which is half the width of what i think your running and i know overcooling can be a problem. Most thermostatic plates dont work like say a coolant thermostat and they allow oil through the cooler all the time even when its below the thermostats temperature. I have read alot of people moaning about the mocal thermostatic plate not working as they would of wanted. You need to get temperature of 100c every now and then just to burn of the moisture and other crap that collects in the oil.

In all honesty, after using the Setrab, I wish I had bought another Fluidyne. Low air flow can still drop the temps dramatically without ducting and it offers the lowest pressure drop of any other cooler I've seen.

#28

Thread Starter

Well just took it out for a drive. I didn't push it much as im still at the stage of not trusting the hoses 100%.

So far no leaks off of any of the fittings which is better than i got with various brands of AN fittings. Running the car all the way up to the top of the redline the oil pressure never drops below 80psi even when vtec engages. Idle pressure at 90c is 16.5 psi which is about the same as what i had before.

Cooling wise even with the higher temperature thermostat it would be hard to keep the engine oil at the right temperature. My oil temp sensor is in the sandwich plate which normally shows about 10c above the sump temperature. Highest i saw today was 93c but you have to remember its quite a hot day and in the winter especially in the UK i would imagine that it could quite easily overcool the oil. Especially as i have removed the stock cooler. I will make up a shield that i can fit for the winter if i have any problems. Sitting at 70mph cruising i think would cause the main problems with overcooling

YamahaSHO. I can see what your saying about ducting and that a fan is not required but i have tested oil temperature today and cruising at 70mph if i switch the fan on i still gets more cooling, the temperatures drops noticeably quicker. Obviously the real test would be to duct it and then drive it and do some sort of comparison. Im not going to duct mine because the car see's maybe 6 trackdays a year and i just want to take the edge off of the heat when im doing those days. If anything during the year i would want to block the cooler to prevent overcooling. I have a trackday on the 22nd July at the same place i got the temperature upto 130c so i will test it then.

So far no leaks off of any of the fittings which is better than i got with various brands of AN fittings. Running the car all the way up to the top of the redline the oil pressure never drops below 80psi even when vtec engages. Idle pressure at 90c is 16.5 psi which is about the same as what i had before.

Cooling wise even with the higher temperature thermostat it would be hard to keep the engine oil at the right temperature. My oil temp sensor is in the sandwich plate which normally shows about 10c above the sump temperature. Highest i saw today was 93c but you have to remember its quite a hot day and in the winter especially in the UK i would imagine that it could quite easily overcool the oil. Especially as i have removed the stock cooler. I will make up a shield that i can fit for the winter if i have any problems. Sitting at 70mph cruising i think would cause the main problems with overcooling

YamahaSHO. I can see what your saying about ducting and that a fan is not required but i have tested oil temperature today and cruising at 70mph if i switch the fan on i still gets more cooling, the temperatures drops noticeably quicker. Obviously the real test would be to duct it and then drive it and do some sort of comparison. Im not going to duct mine because the car see's maybe 6 trackdays a year and i just want to take the edge off of the heat when im doing those days. If anything during the year i would want to block the cooler to prevent overcooling. I have a trackday on the 22nd July at the same place i got the temperature upto 130c so i will test it then.

#29

Thread Starter

It was the 1/2" bsp to AN10 adaptors that I drilled out as they had the smallest inner diameter of anything.

My cooler is a full width Setrab 16 row. It's mounted very low, the hoses too so that no oil can drain back to the sump when the engine's not running. It does mean the lower part of the cooler might not get much air flow though.

My cooler is a full width Setrab 16 row. It's mounted very low, the hoses too so that no oil can drain back to the sump when the engine's not running. It does mean the lower part of the cooler might not get much air flow though.

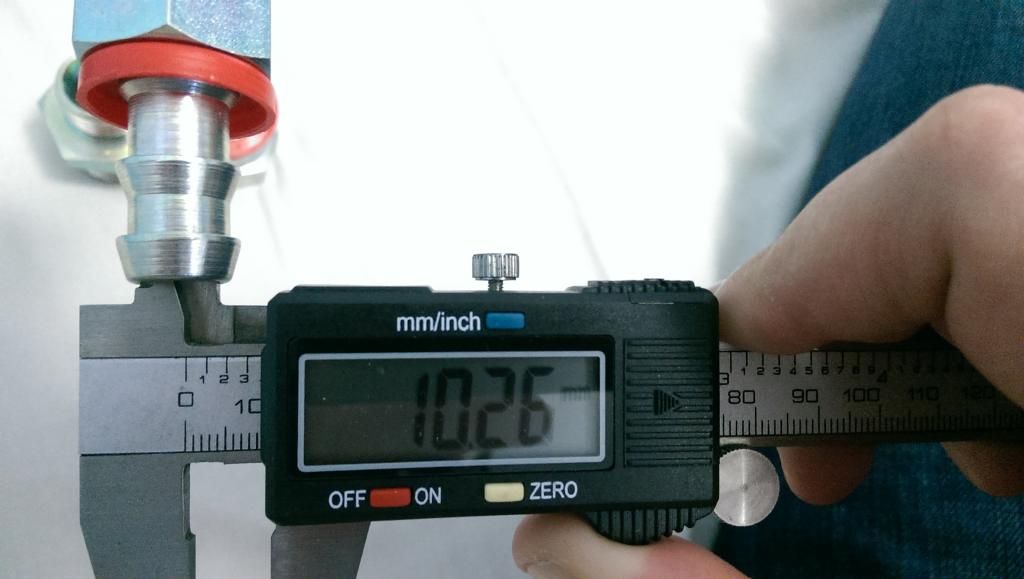

1/2 BSP male to male, 5/8 bsp to an10 hose, 1/2 BSP to AN8 hose

Iam currently running the 1/2 bsp hose with 1/2 bsp push fittings but you dont get anywhere near 1/2 (13mm) flow with the push fittings.

The 5/8 bsp fittings to AN10 hose work out as

The 1/2 BSP male to male fitting

It doesnt seem much but it makes a huge difference to the cross sectional area of the hose and i would imagine the amount it can flow.

One thing i can say for sure is that 1/2 BSP fittings do restrict the flow alot because as soon as my thermostatic sandwich plate begins to push more oil through the cooler rather than bypassing it i suffer alot of pressure drop. I lose 15psi during vtec engagement compared to before and at idle its dropping down to 14psi with the oil only at 93c. If i slip the clutch then it actually shows less than 10psi as the revs drop down. The spa gauges are very accurate, sometimes too accurate so i might have a look at changing the sampling rate because it seems to fast at the moment.

I have ordered my 5/8 bsp hoses to run to the cooler and hopefully it will make a noticeably difference to the pressure drops.

When the hoses arrive i will also ditch the pressure and oil temp sandwich plate and put them in the sump and the OEM oil pressure switch place. It seems like its the best place to measure pressure

Thread

Thread Starter

Forum

Replies

Last Post