String Alignment Calculator

#1

Hey guys, I mentioned before about making a string alignment calculator. This is the spreadsheet I use but I know there are others out there. This is the only one I have seen that will do camber and caster, not just toe. If you are detail oriented, you can get better and more repeatable results than with a computer alignment machine. When you check caster, it automatically pulls some readings from the other tabs. Start by sweeping left by 90 degrees and taking measurements. The toe in this measurement should be perpendicular to the string, not the wheel. After you get your measurement sweep back to center and recheck that your strings are still parallel. Repeat with the right sweep. I included a fractional table because reading with a fractional scale is really fast, but I suppose if you used some digital calipers you could theoretically increase you're accuracy.

Here is the download link: v1.3. Download and enjoy.

Remember that your results are only limited by your attention to detail. I won't go into the process of how to actually set up, there's plenty of resources available for that like this. Remember that your track widths are different front to rear and the strings must be parallel to the centerline of the car. If you have any questions about how to use the sheet let me know. I nor s2ki.com will be held liable for your use or misuse of this spreadsheet.

I probably have seen it. I've looked at almost every one out there and wasn't really satisfied with them, which is why I put this together. I think you might be able do it that way but I just like knowing I'm parallel with the car I guess!

If I'm doing a full alignment, my work order goes like this; set rear camber, set rear toe, double check each after (crosstalk effects), check front camber and front toe, do steering sweeps and get caster measurement and adjust if you wish, recheck starting camber/ toe, adjust until camber/ caster combo is what you want, set front toe. The caster adjuster has a lot of crosstalk with the camber and a little with the toe so you typically have to do at least a couple iterations to get where you want. If you don't mess with caster it goes so much faster!

That's 90 degrees steering wheel angle. The actual number really doesn't matter as long as you get pretty close either way. 90 is just an arbitrary number that's easy to eyeball. If you were doing a car with a really slow steering rack ratio I'd probably go 180 degrees at the steering wheel. IIRC, a 90 degree steering wheel angle results in about 5-10 degrees wheel angle.

I hope you all enjoy!

Here is the download link: v1.3. Download and enjoy.

Remember that your results are only limited by your attention to detail. I won't go into the process of how to actually set up, there's plenty of resources available for that like this. Remember that your track widths are different front to rear and the strings must be parallel to the centerline of the car. If you have any questions about how to use the sheet let me know. I nor s2ki.com will be held liable for your use or misuse of this spreadsheet.

Have you seen the one that only requires the strings to be parallel to each other and not dependent on car centerline? I assume it just takes the measurements then adds them together and divides by 2. It's posted in the diy alignment thread iirc.

If I'm doing a full alignment, my work order goes like this; set rear camber, set rear toe, double check each after (crosstalk effects), check front camber and front toe, do steering sweeps and get caster measurement and adjust if you wish, recheck starting camber/ toe, adjust until camber/ caster combo is what you want, set front toe. The caster adjuster has a lot of crosstalk with the camber and a little with the toe so you typically have to do at least a couple iterations to get where you want. If you don't mess with caster it goes so much faster!

When you say "sweeping left by 90 degrees" are you talking about turning the steering wheel 90* from straight ahead? Iirc aren't caster measurements done with 20* angle of the wheel (front wheel being measured not the "steering" wheel)? So does this mean that 90* steering angle = 20* front wheel angle?

Sorry just trying to make sure I understand the intent properly.

Sorry just trying to make sure I understand the intent properly.

#2

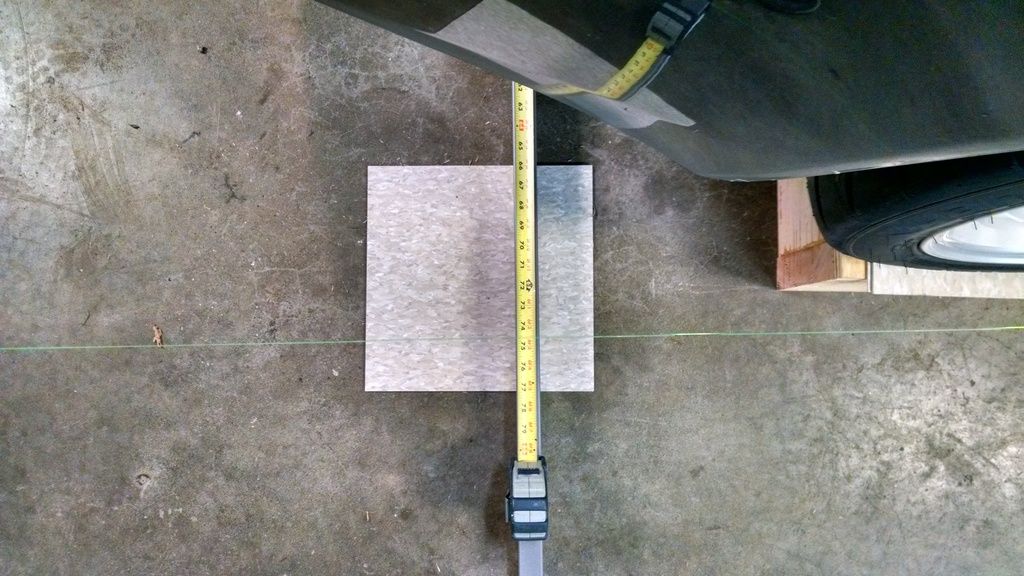

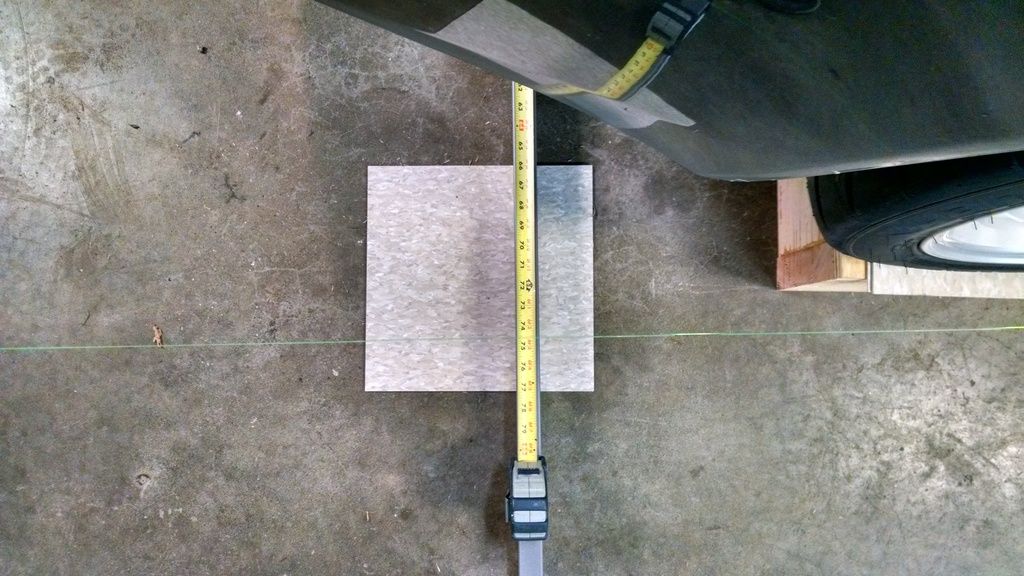

This picture shows a lot of detail of my typical alignment setup. First of all, you'll notice I have the car up on these big blocks to get it high enough off the ground to reach the adjusters and swing my tools. Next, you'll notice I have vinyl floor tiles underneath each wheel. They serve two purposes; they account for my floor not being level and they make great slip plates with a little bit of grease between the top two tiles, allowing the wheel to turn freely and minimizing suspension bind. Next you'll see the jackstands on each corner. On the front and the rear is a piece of steel electrical conduit. I tie fishing line on each end and run it down the side. Finally, the eight foot level and tape measure on the floor is for measuring the distance between the strings. I use a square off of the level to line it up with the strings. The strings are parallel when the distance across is the same front to back. The tricky part is finding the perfect hub to string distance that will get your strings perfectly parallel. In this particular alignment, I had 5" at the front and 4 7/32" at the rear. You will have to figure this out for yourself because it will be different for nearly every car.

#3

Excellent and informative post, thanks for sharing

#4

#5

Good write up freetors thanks for sharing

How tall are your blocks ? and can you get to all the adjusters

I'm nearly finished replacing the bolts and bushes on mine so need to do the alignment, will do Camber then Caster then tracking

How tall are your blocks ? and can you get to all the adjusters

I'm nearly finished replacing the bolts and bushes on mine so need to do the alignment, will do Camber then Caster then tracking

#6

Trending Topics

#8

Did the car ever roll off those stands? I've had it happen with a race car that just landed on the frame. On a street car it could be damaging. I've since added a stop so it can't roll off.

You may also find this $80 tool useful: http://www.advancedr...tring_gauge.php . Like most systems, it is subject to wheel rim runout. Remember, when using the wheel for reference you are subject to not only the wheel being off, but the flange being off.

You could also use rotary lasers instead of strings. Harbor Freight has one that would be $48 with a 20% coupon; Home Depot has one for $70. Less fussy compared to the string.

Update: I fixed the link.

You may also find this $80 tool useful: http://www.advancedr...tring_gauge.php . Like most systems, it is subject to wheel rim runout. Remember, when using the wheel for reference you are subject to not only the wheel being off, but the flange being off.

You could also use rotary lasers instead of strings. Harbor Freight has one that would be $48 with a 20% coupon; Home Depot has one for $70. Less fussy compared to the string.

Update: I fixed the link.

#9

Did the car ever roll off those stands? I've had it happen with a race car that just landed on the frame. On a street car it could be damaging. I've since added a stop so it can't roll off.

You may also find this $80 tool useful: http://www.advancedracing.com/dream_...ring_gauge.php. Like most systems, it is subject to wheel rim runout. Remember, when using the wheel for reference you are subject to not only the wheel being off, but the flange being off.

You could also use rotary lasers instead of strings. Harbor Freight has one that would be $48 with a 20% coupon; Home Depot has one for $70. Less fussy compared to the string.

You may also find this $80 tool useful: http://www.advancedracing.com/dream_...ring_gauge.php. Like most systems, it is subject to wheel rim runout. Remember, when using the wheel for reference you are subject to not only the wheel being off, but the flange being off.

You could also use rotary lasers instead of strings. Harbor Freight has one that would be $48 with a 20% coupon; Home Depot has one for $70. Less fussy compared to the string.

#10

I've been playing around with this since then and have fixed a few minor errors like the wrong sign on the caster result. I have also moved a couple fields around to make them in a more logical order. I have also changed number formats to fractions in many places since most American users will be using this with standard measures. Finally, I added a direct input option on the camber and caster pages for users that own a camber/caster gauge (I recently bought a digital longacre unit and it's pretty neat!).

Here is the link for V1.3

Here is the link for V1.3

Thread

Thread Starter

Forum

Replies

Last Post