Is my alignment ok for daily driving?

#21

Rolling resistance is more of an issue with some tires than others. I measured a 6% decrease in torque across the whole RPM range in 3rd gear when I switched from Sumitomo HTRZ II's to Hankook RS-3's using my CAN dyno. I believe that's over 50 lbs of force pulling the front wheel backward (toeing the wheel out).

Also, any toe-in will give more drag than pure "rolling resistance with zero toe.

Anyway, with minimal toe front and rear, it shouldn't take anything like 200 lb to roll your car on a flat level surface.

The last front tires I replaced were Hankook RS-3's, and I probably got 15K miles out of them. However, I had to flip them over on the wheels to move the heavily worn inner shoulder to the outside of the wheel. I had very close to 0 toe with about -0.7 degrees camber.

That said, we do have VERY, VERY abrasive (and grippy) concrete roads, which I'm sure decreases tire life dramatically.

#22

Registered User

Join Date: Jan 2006

Location: 17 ft below sea level.

Posts: 4,949

Likes: 0

Received 21 Likes

on

16 Posts

but then again the infamous UK spec gives a range from 0.67degrees to 1.33 degrees!). The UK spec is almost certainly erroneous, as it gives exactly TWICE recommended rear to vs. the US spec of 0.32 degrees to 0.64degrees total.

In my experience on the street and track, adding rear toe for "stability" simply doesn't work. Kills straight-line stability, but also kills turn-in pointability.

Short version: I hate rear toe. It sucks for everything. Really.

In my experience on the street and track, adding rear toe for "stability" simply doesn't work. Kills straight-line stability, but also kills turn-in pointability.

Short version: I hate rear toe. It sucks for everything. Really.

0'20" per side, no?

I've been using this for years now and like it.

But I don't know what I've been missing, according to your comments.

#23

Actually, 0'20" (zero arcminutes, 20 arcseconds) would be 0.006 degrees, or zero toe. I would run that before running 0[sup]o[/sup] 20' per side, though (0.33deg per side, 0.67deg total), which is of course what everyone assumes they meant where they have 0[sup]o[/sup]20"

What your missing if you're running 20 arcminutes of toe-in per side (0.33deg per side, 0.67deg total) instead of less than half that:

2x-3x or even more tire life

Better straight line stability (particularly in traction-challenged conditions or bumpy/undulating pavement)

Better turn-in when you want the car to point

Less drag => better mileage (measurable) and better acceleration

Grinding tires away in the name of "stability" is in my experience (I did try it) a promise not delivered on by big toe-in. It is a waste of tire grip and life to have the rears continuously work against each other, grinding themselves away. In my experience, way less rear toe feels a LOT better, more stable, more responsive and gives radically reduced tire wear.

IMO, dragging an anchor behind the car makes about as much sense as ridiculously high toe-in.

Try running half that rear toe or less (I generally run 0.2deg total in back) and see what you think.

I *have* tried 0.64degrees total rear toe (and inadvertently more than that once!) and it SUCKED, BAD, for EVERYthing!

I've been using this for years now and like it.

But I don't know what I've been missing, according to your comments.

But I don't know what I've been missing, according to your comments.

2x-3x or even more tire life

Better straight line stability (particularly in traction-challenged conditions or bumpy/undulating pavement)

Better turn-in when you want the car to point

Less drag => better mileage (measurable) and better acceleration

Grinding tires away in the name of "stability" is in my experience (I did try it) a promise not delivered on by big toe-in. It is a waste of tire grip and life to have the rears continuously work against each other, grinding themselves away. In my experience, way less rear toe feels a LOT better, more stable, more responsive and gives radically reduced tire wear.

IMO, dragging an anchor behind the car makes about as much sense as ridiculously high toe-in.

Try running half that rear toe or less (I generally run 0.2deg total in back) and see what you think.

I *have* tried 0.64degrees total rear toe (and inadvertently more than that once!) and it SUCKED, BAD, for EVERYthing!

#24

there's no way on earth your apparent 6% is down to rolling resistance. NO properly inflated, non-defective tire you could fit would give you 50 lb of drag each due to rolling resistance. Something else going on for sure. Possibly the tire is slipping more under load, that would show up as reduced power and torque.

Also, any toe-in will give more drag than pure "rolling resistance with zero toe.

Anyway, with minimal toe front and rear, it shouldn't take anything like 200 lb to roll your car on a flat level surface.

Also, any toe-in will give more drag than pure "rolling resistance with zero toe.

Anyway, with minimal toe front and rear, it shouldn't take anything like 200 lb to roll your car on a flat level surface.

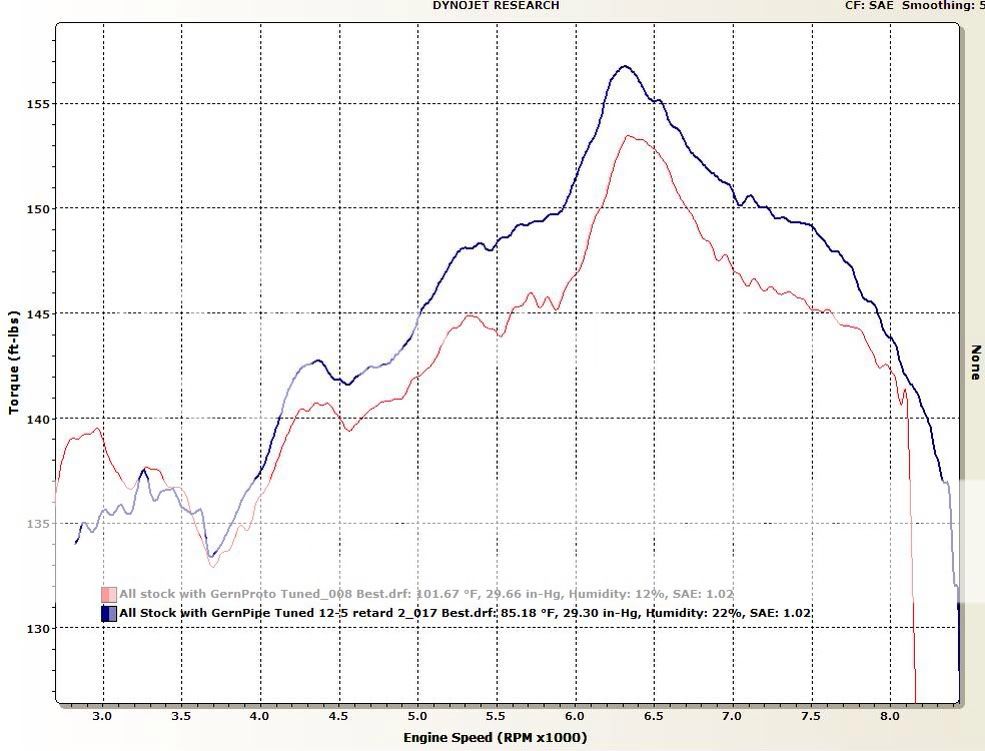

It just occurred to me that I also have DynoJet results from the RS-3's and HTRZ II's. The change in torque here is just half what would be shown on my CAN Dyno, since the DynoJet is only impacted by the rolling resistance of 2 tires instead of 4. There's no slippage either, since my car doesn't even make enough power for that. Another thing to note is that the humidity sensor on the dyno was WAY off, showing only 22% when it was POURING down rain outside during the runs on the HTRZ's.

#25

If there is a 6% loss (not saying and wasn't saying there isn't), it is not due to base tire rolling resistance (minus toe effects and slip effects).

If you're applying power, there is slippage, always. Just like if you're generating cornering forces, you are operating at *some* slip angle.

Effective rolling resistance will change DRAMATICALLY with small changes in slippage. And at full-throttle, even with an S2k, the slippage is much much much greater than at cruise throttle or coasting.

What static front/rear toe were you running again? Zero front if I recall, ??? rear? Any toe at all will induce more drag with a tire that generates more grip per slip angle. If you are running UK-spec toe, I'd honestly suspect that is the lion's share of loss with the RS-3s.

What I am saying is that a 6% loss in torque under WOT conditions is not related to zero-torque (and minimal toe) tire rolling resistance. I.e., if the RS-3's are costing you that much with some toe and under max throttle conditions, they aren't costing you anything like that under cruise conditions with minimal toe. Certainly they wouldn't be giving you the 50 lb of rolling resistance drag per tire (6% * 150 lb-ft * 1.35 4th gear trans ratio * 4.1 diff /1 ft. tire rolling radius = 50 lb., just like you called it) while cruising at light throttle. Even less so with minimal toe.

50 lb. drag for rolling resistance alone (no torque/slippage or toe effects) would equate to .067 RR coefficient. ANY modern tire properly inflated is going to be 1/4 of that or less.

If you're applying power, there is slippage, always. Just like if you're generating cornering forces, you are operating at *some* slip angle.

Effective rolling resistance will change DRAMATICALLY with small changes in slippage. And at full-throttle, even with an S2k, the slippage is much much much greater than at cruise throttle or coasting.

What static front/rear toe were you running again? Zero front if I recall, ??? rear? Any toe at all will induce more drag with a tire that generates more grip per slip angle. If you are running UK-spec toe, I'd honestly suspect that is the lion's share of loss with the RS-3s.

What I am saying is that a 6% loss in torque under WOT conditions is not related to zero-torque (and minimal toe) tire rolling resistance. I.e., if the RS-3's are costing you that much with some toe and under max throttle conditions, they aren't costing you anything like that under cruise conditions with minimal toe. Certainly they wouldn't be giving you the 50 lb of rolling resistance drag per tire (6% * 150 lb-ft * 1.35 4th gear trans ratio * 4.1 diff /1 ft. tire rolling radius = 50 lb., just like you called it) while cruising at light throttle. Even less so with minimal toe.

50 lb. drag for rolling resistance alone (no torque/slippage or toe effects) would equate to .067 RR coefficient. ANY modern tire properly inflated is going to be 1/4 of that or less.

#26

The 6% drop in torque occurred the very day I replaced the HTRZII's with RS-3's, and stayed that way until the very day I replaced those RS-3's with new HTRZII's. I literally mean "the very day", since I was doing many CAN Dyno pulls each day at that time while developing my exhaust prototype. (endless cycle of cutting, welding, retuning, street dyno, sleep, repeat, repeat, repeat).

Slippage is definitely NOT the issue, since slippage would cause my CAN Dyno to read higher, unlike a DynoJet where slippage would cause it to read lower. Since the DynoJet agrees with my CAN Dyno, It has to be due to rolling resistance.

I agree that rolling resistance will go up with more toe, and will go up even more with grippy tires. However, I don't see how 0.25 degrees total toe-in on the rear and 0.06 degrees toe-in on the front could be that big of a contributor. I think it's mostly due to the RS-3's just having a very soft internal structure, giving it a lot of rolling resistance. I remember in the 90's, when the Hoosier autocross tires were bias plies, and had tremendous amounts of rolling resistance compared to the radials that most people used (BFG R1's ,etc.). A car with Hoosiers could not be pushed forward in grid unless there were multiple people pushing, but it was simple to push the cars with radials.

Slippage is definitely NOT the issue, since slippage would cause my CAN Dyno to read higher, unlike a DynoJet where slippage would cause it to read lower. Since the DynoJet agrees with my CAN Dyno, It has to be due to rolling resistance.

I agree that rolling resistance will go up with more toe, and will go up even more with grippy tires. However, I don't see how 0.25 degrees total toe-in on the rear and 0.06 degrees toe-in on the front could be that big of a contributor. I think it's mostly due to the RS-3's just having a very soft internal structure, giving it a lot of rolling resistance. I remember in the 90's, when the Hoosier autocross tires were bias plies, and had tremendous amounts of rolling resistance compared to the radials that most people used (BFG R1's ,etc.). A car with Hoosiers could not be pushed forward in grid unless there were multiple people pushing, but it was simple to push the cars with radials.

#27

The 6% drop in torque occurred the very day I replaced the HTRZII's with RS-3's, and stayed that way until the very day I replaced those RS-3's with new HTRZII's. I literally mean "the very day", since I was doing many CAN Dyno pulls each day at that time while developing my exhaust prototype. (endless cycle of cutting, welding, retuning, street dyno, sleep, repeat, repeat, repeat).

Slippage is definitely NOT the issue, since slippage would cause my CAN Dyno to read higher, unlike a DynoJet where slippage would cause it to read lower.

Slippage will affect apparent rolling resistance, and at max torque, slippage will be profoundly different than under cruise conditions.

What gear were you doing these runs in? If in a low gear, MUCH greater tire slippage.

Since the DynoJet agrees with my CAN Dyno, It has to be due to rolling resistance.

Would be useful to do multiple coast-downs over the same stretch of road on RS-3 vs. HTRZII if you *really* want to know what the difference in actual rolling resistance is, unrelated to tire slip under load.

I agree that rolling resistance will go up with more toe, and will go up even more with grippy tires. However, I don't see how 0.25 degrees total toe-in on the rear and 0.06 degrees toe-in on the front could be that big of a contributor. I think it's mostly due to the RS-3's just having a very soft internal structure, giving it a lot of rolling resistance.

I remember in the 90's, when the Hoosier autocross tires were bias plies, and had tremendous amounts of rolling resistance compared to the radials that most people used (BFG R1's ,etc.). A car with Hoosiers could not be pushed forward in grid unless there were multiple people pushing, but it was simple to push the cars with radials.

Anyway, I now the slippage in the dyno runs you're doing is quite small compared to *really* spinning the tires, but relative to zero torque loading on the tires, still very significant vis a vis apparent "rolling resistance".

Something you could do regarding running toe-in up front to counter any toeing out due to tire drag (which I still think is the wrong approach):

Do some CAN dyno runs, go to alignment shop and see what the front toe was, then add (or subtract) maybe 0.2 degrees total, repeat test, go BACK to the alignment shop, have them change front toe back to the original setting, and CAN dyno test again.

Then do the same with rear toe.

That would at least have a chance of pointing you in the right direction.

#28

Old info (1971) on rolling resistance vs. tire slip in Fig 1.14, page 16, here: http://media.wiley.com/product_data/...0471354619.pdf

Note that an S2000 with 150 lb-ft of torque should be capable of a "tractive effort coefficient" (tractive force divided by normal force) of over 1 in 1st gear,~0.5 in 4th gear, ~0.4 in 5th.

Chart shows rolling resistance just about TRIPLING at 0.4 tractive effort coefficient (~650 lb thrust at rear wheels on S2k) vs. freewheeling.

Even though tire slip is minimal relative to *spinning* the tires, it is still significant as far as rolling resistance is concerned, even in a torqueless S2000 in 5th gear.

Note that an S2000 with 150 lb-ft of torque should be capable of a "tractive effort coefficient" (tractive force divided by normal force) of over 1 in 1st gear,~0.5 in 4th gear, ~0.4 in 5th.

Chart shows rolling resistance just about TRIPLING at 0.4 tractive effort coefficient (~650 lb thrust at rear wheels on S2k) vs. freewheeling.

Even though tire slip is minimal relative to *spinning* the tires, it is still significant as far as rolling resistance is concerned, even in a torqueless S2000 in 5th gear.

#29

That's a good link, thanks for posting it. I have quoted a few paragraphs below.

The rolling resistance of tires on hard surfaces is primarily caused by the hysteresis in tire materials due to the deflection of the carcass while rolling. Friction between the fire and the road caused by sliding, the resistance due to air circulating inside the tire, and the fan effect of the rotating tire on the surrounding air also contribute to the rolling resistance of the tire, but they are of secondary importance. Available experimental results give a breakdown of tire losses in the speed range 128–152 km/h (80–95 mph) as 90–95% due to internal hysteresis losses in the tire, 2–10% due to friction between the tire and the ground, and 1.5–3.5% due to air resistance [1.5, 1.6]. Of the total energy losses within the tire structure, it is found that for a radial truck tire, hysteresis in the tread region, including the belt, contributes 73%, the sidewall 13%, the region between the tread and the sidewall, commonly known as the shoulder region, 12%, and the beads 2%.

When a tire is rolling, the carcass is deflected in the area of ground contact. As a result of tire distortion, the normal pressure in the leading half of the contact patch is higher than that in the trailing half. The center of normal pressure is shifted in the direction of rolling. This shift produces a moment about the axis of rotation of the tire, which is the rolling resistance moment. In a free-rolling tire, the applied wheel torque is zero; therefore, a horizontal force at the tire–ground contact patch must exist to maintain equilibrium. This resultant horizontal force is generally known as the rolling resistance. The ratio of the rolling resistance to the normal load on the tire is defined as the coefficient of rolling resistance.

A number of factors affect the rolling resistance of a pneumatic tire. They include the structure of the tire (construction and materials) and its operating conditions (surface conditions, inflation pressure, speed, temperature, etc.). Tire construction has a significant influence on its rolling resistance. Figure 1.3 shows the rolling resistance coefficient at various speeds of a range of bias-ply and radial-ply passenger car tires at rated loads and inflation pressures on a smooth road [1.7]. The difference in rolling resistance coefficient between a bias-ply and a radial-ply truck tire of the same size under rated conditions is shown in Fig. 1.4 [1.8]. Thicker treads and sidewalls and an increased number of carcass plies tend to increase the rolling resistance because of greater hysteresis losses. Tires made of synthetic rubber compounds generally have higher rolling resistance than those made of natural rubber. Tires made of butyl rubber compounds, which are shown to have better traction and roadholding properties, have an even higher rolling resistance than those made of conventional synthetic rubber. It is found that the rolling resistance of tires with tread made of synthetic rubber compounds and that made of butyl rubber compounds are approximately 1.06 and 1.35 times that made of natural rubber compounds, respectively.

There were lots of other interesting things that I thought about quoting. It talked about the relationship between inflation pressure and / or internal stiffness combined with various road surfaces, which indicated that in my case (hard concrete), a stiffer internal construction and higher tire pressures would reduce rolling resistance due to less deflection within the tire.

#30

My CAN Dyno uses the high resolution speed data from the VSA / ABS system when it is connected to the CAN interface (OBDII). However, when I run it off-line using FlashPro datalogs, it uses the engine RPM, which is slightly more "noisy". I use 3rd gear for the pulls.

I may try adjusting my toe in or out to see how it impacts the CAN dyno results, but I wouldn't take it to an alignment shop for that. Every 1/4 turn of the front tie rod equates to 0.16 degrees.

I'm not sure how much of the rolling resistance is due to engine torque, but it seems that the DynoJet results indicate that the rear thres aren't responsible for the whole 6%. If I find time to test this out, I will do some CAN Dyno runs with RS-3's on the front only, rear only, front and rear, or not at all. I have 4 new RS-3's mounted on my car right now...

I may try adjusting my toe in or out to see how it impacts the CAN dyno results, but I wouldn't take it to an alignment shop for that. Every 1/4 turn of the front tie rod equates to 0.16 degrees.

I'm not sure how much of the rolling resistance is due to engine torque, but it seems that the DynoJet results indicate that the rear thres aren't responsible for the whole 6%. If I find time to test this out, I will do some CAN Dyno runs with RS-3's on the front only, rear only, front and rear, or not at all. I have 4 new RS-3's mounted on my car right now...