DIY Valve Adjustment

#111

I like reading the plugs mostly, they can tell you quite a bit about your engine's operation if one knows what to look for.

#112

Registered User

When i loose the nut on the rocker arm, i notice that the rocker arm can move up and down very little (1-2mm)! Is that normal? And if yes, when i put the feeler gauge in the gap should the rocker arm be pushed up or down? Thank you!

#113

What you're checking for with the feeler gauge is the distance between the rocker arm and the valve stem tip(ie with the rocker arm unloaded and lifted all the way up), that little bit of motion reduces as the parts expand under heat. You leave a cold clearance so when the parts expand, the valves aren't constantly exposed and actually seat themselves. Especially at low rpms. If the clearance is too great, you will get valve clatter, heck even if you adjust the valves perfectly to spec, you will get valve clatter, but if you did it right all the clearances will be just right and homogenous. So basically the clatter blends into each other like a harmony and becomes almost imperceptible. Truthfully, I intentionally leave the valves towards the looser end of the spectrum in all the cars I do. They all have a little valve clatter, but it's super feint you have to purposefully listen for it, but it's not a clicking sound, more like a well oiled sewing machine stitching silk.

#115

To my knowledge adjusting to the tight end is not recommended. Valves in these cars tighten over time after an adjustment which means you would be out of spec shortly. This would be especially bad for a DBW model (06-09). You would also have a louder valvetrain going this route.

#117

Sorry to bump this thread up but I'm really confused and I'm not sure what to think.

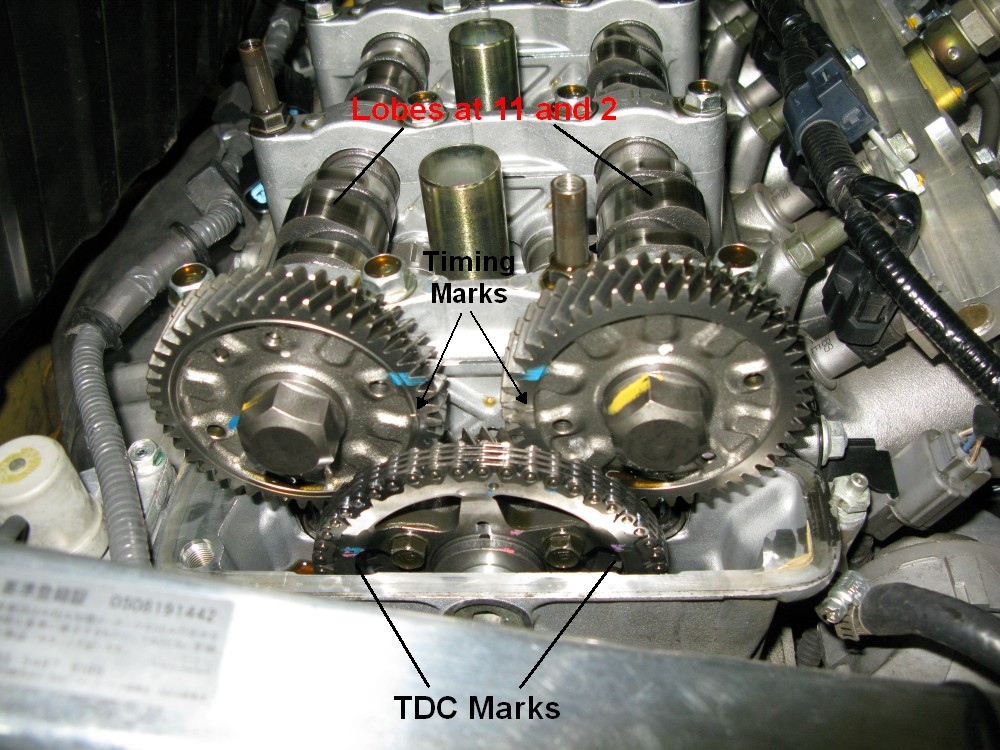

Check these pictures please.

All TDC marks lined up like they suppose to when to check cylinder #1

But why are cam lobes on cylinder #4 in position and not #1

Is my cams installed the wrong way or what is going on?

Car has been running great and I hope there is just some stupid mistake in my head.

I've never checked the valves on my S2000 before.

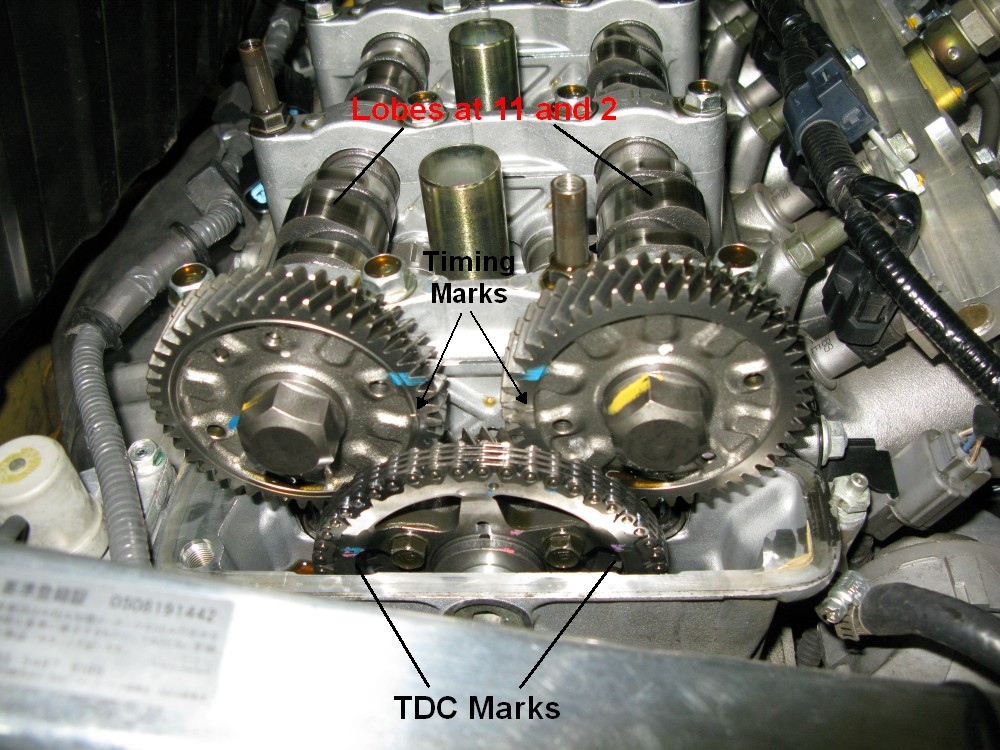

Check these pictures please.

All TDC marks lined up like they suppose to when to check cylinder #1

But why are cam lobes on cylinder #4 in position and not #1

Is my cams installed the wrong way or what is going on?

Car has been running great and I hope there is just some stupid mistake in my head.

I've never checked the valves on my S2000 before.

#118

When #1 is a TDC, so is #4. But they're at different intervals of the combustion process. One has just pushed out all of it's exhaust while the other has combusted and compressed it's combustion pressure... if I have that right. Looks good to me.

#119

Thanks for the response.

I was following this guide https://robrobinette.com/S2000ValveAdjust.htm but got confused because the lobes didn't ad up with my markings.

And if I check the clearance with the lobes pointing down I can't even get a 0.1mm feeler in there.

I was following this guide https://robrobinette.com/S2000ValveAdjust.htm but got confused because the lobes didn't ad up with my markings.

And if I check the clearance with the lobes pointing down I can't even get a 0.1mm feeler in there.

#120

This is why I advocate ignoring the timing marks. Too easy to get confused.

Instead, turn motor until lobes for cylinder to be set are pointing more or less up, adjust those valves.

So long as lobes are up, its safe to adjust those valves. Much faster, and safer, and less stressful, to do it this way.

Sent from my SM-G920P using IB AutoGroup

Instead, turn motor until lobes for cylinder to be set are pointing more or less up, adjust those valves.

So long as lobes are up, its safe to adjust those valves. Much faster, and safer, and less stressful, to do it this way.

Sent from my SM-G920P using IB AutoGroup