Clutch issue at low rpm’s - High rpms mask issue

#51

Thread Starter

Is the release bearing guide in the small space between the pressure plate and fork area? So closer to the pressure plate? I saw a small circular area, about 1/3 of an inch wide and not sure if that’s where the grease should go.

#52

Thread Starter

Yea I think I went a little grease happy but wanted to make sure I didn’t miss anything. Was tough getting the fork tips greased with my angle.

here is another video. Maybe this will help show a bit more.

here is another video. Maybe this will help show a bit more.

#53

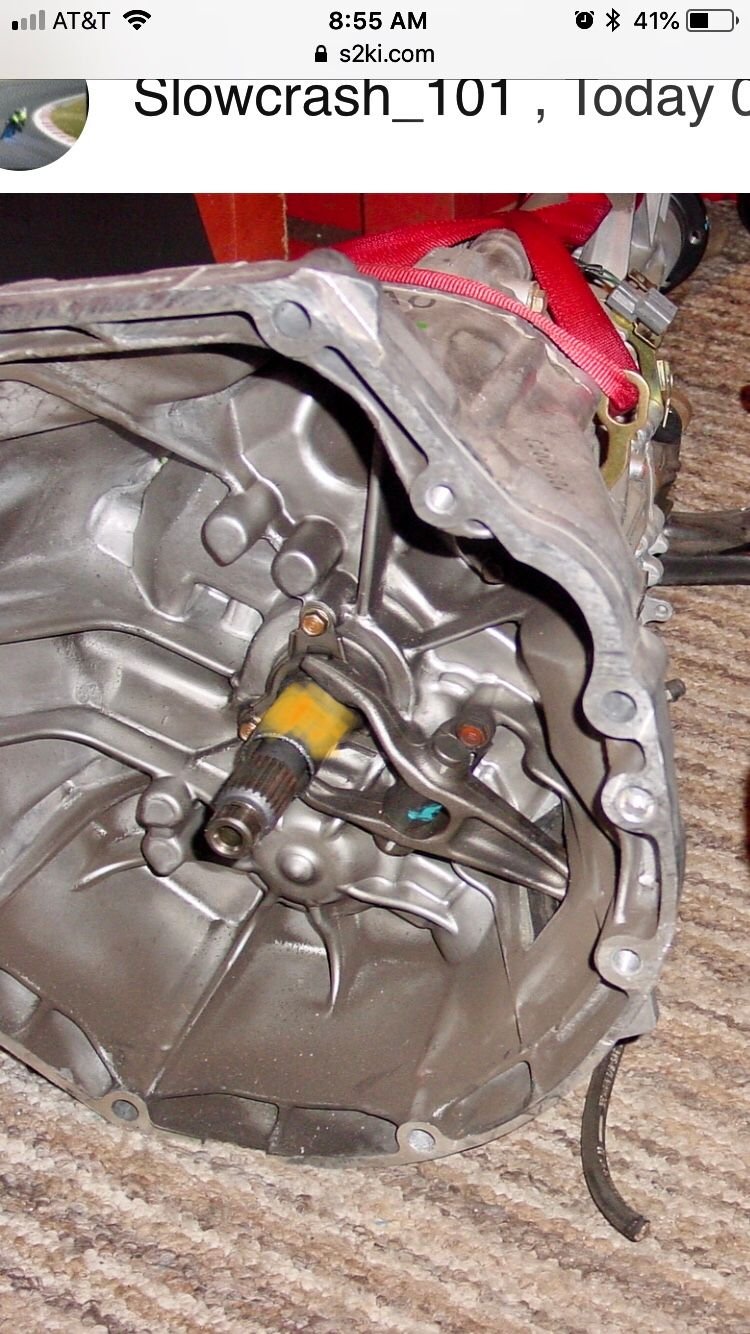

the release bearing sits on the guide, the PP bolts to the flywheel and sandwiches the friction disk which sits on the splines of the transmission input shaft. The fork slots into a spring (The greased up part in your pics) that spring is the pivot. The end of the fork slots over the release bearing.

#54

Thread Starter

Thanks for the pics slow crash. So from the video does everything seemed greased? I know I put a lot more pretty much everywhere when I took the slave down, it seemed the slave hinge connector was the only spot I saw grease. The tips looked pretty dry.

i drove it after and I didn’t notice much of a change after putting all the grease in. Maybe it will get better with time but looking at options to get a second opinion since I’m having the same symptoms as before the swap and find it hard to believe but my act pp and oem pp were broke/defective at the same time.

i drove it after and I didn’t notice much of a change after putting all the grease in. Maybe it will get better with time but looking at options to get a second opinion since I’m having the same symptoms as before the swap and find it hard to believe but my act pp and oem pp were broke/defective at the same time.

#55

Thread Starter

Question about the guide. I see it clearly with your pictures but when you remove the slave, and click out the fork, the main thing I see is the fork tips and the fork middle clip connection. From the pics, it seems I need to just put grease behind the fork clip connector. Pretty much the part You are unable to see from the slave opening since the clip is in the way.

I mainly focused on the part in front of the tip, closer to the clutch. Should I take the slave off again and just spray lithium grease behind the fork clip connector to see if I notice any improvement? I can try again with the close hanger but wouldn’t be able to see what I’m hitting.

So everything highlighted in yellow.

I know I’m not using the right grease but want to diagnose the problem.

#56

Moderator

Greasing the fork pivot is not necessary as the shaft moves in the fork (stationary in the bracket) Only thin oil will make it’s way into the fork shaft pivot.

Fork tips, ball end, and guide collar are key grease points.

Fork tips, ball end, and guide collar are key grease points.

#57

Thread Starter

Update:

I bought some spray grease and I’m feeling the difference as I continue to drive. The notchy feeling was there initially after the spray but much less. Was stuck in traffic and as I continued to drive, the notchy feeling occurs much less. Out of 10 clutch pushes, may feel it 1-2 times. Will see how it feels later but so far it seems to be working better. Not sure how long this grease will last but now I know it looks to be grease related.

I bought some spray grease and I’m feeling the difference as I continue to drive. The notchy feeling was there initially after the spray but much less. Was stuck in traffic and as I continued to drive, the notchy feeling occurs much less. Out of 10 clutch pushes, may feel it 1-2 times. Will see how it feels later but so far it seems to be working better. Not sure how long this grease will last but now I know it looks to be grease related.

#59

Thread Starter

Seems like it.

Just drove over it again and Now it seems to come and go. I used some junk advance auto spray grease but initially the clutch felt great. I only let it sit for a few minutes and I believe they recommend 30 to let it dry. Still I would have though that grease would have lasted a bit longer but I know it’s not really meant for that.

Once I get my endoscope camera, I’ll now invest in some urea grease and re apply since it seemed to have done the trick for a bit.

Just drove over it again and Now it seems to come and go. I used some junk advance auto spray grease but initially the clutch felt great. I only let it sit for a few minutes and I believe they recommend 30 to let it dry. Still I would have though that grease would have lasted a bit longer but I know it’s not really meant for that.

Once I get my endoscope camera, I’ll now invest in some urea grease and re apply since it seemed to have done the trick for a bit.

#60

Thread Starter

Went to another mechanic and he said it’s the guide not being greased properly since everything else looked ok. Also said the pressure plate wouldn’t cause that noise/sound and notchy feeling.

I received by endoscope and had him take some videos of the issue. What do you guys think? I was going to reach out to the mechanic who did it again but he is stuck on blaming the pressure plate. I did notice a rusted piece on the video but not sure if that makes any difference.

Here are the videos.

I received by endoscope and had him take some videos of the issue. What do you guys think? I was going to reach out to the mechanic who did it again but he is stuck on blaming the pressure plate. I did notice a rusted piece on the video but not sure if that makes any difference.

Here are the videos.