CAR #7 ONE broken exhaust retainer

#71

Registered User

Originally Posted by BADD-S2K,May 11 2007, 09:55 AM

I've watched Billman adjust all 16 of my valves, and whatever he does, it works! He even made a custom tool to get to those hard to reach valves. I'd listen to what he has to say about it or just let him adjust your valves instead of doing it yourself.

#74

Registered User

Join Date: Feb 2004

Location: Dry Branch

Posts: 7,087

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by SpitfireS,May 11 2007, 04:49 AM

There is no real copyright on posted stuff and I think xviper would be the last to claim it so I would like to post this (his  ) line of thought:

) line of thought:

xviper posted on another forum some time ago:

some time ago:

It makes perfect sense to me.

Maybe this rapid change in rpm confuses add-on electronics like a Modify Shifter Beeper as well and it starts giving weird readings.

) line of thought:

) line of thought:xviper posted on another forum

some time ago:

some time ago:It makes perfect sense to me.

Maybe this rapid change in rpm confuses add-on electronics like a Modify Shifter Beeper as well and it starts giving weird readings.

In summary, I don't think there is a problem with the F20C retainers as long as they are not abused. Abuse certainly includes, but is not limited to, money shifts. Nothing Billman or XViper or anyone else has ever suggested has given me any reason to believe that this is not the case, so I'm going to run my retainers until they fail (or until we have to tear into the head for some other reason). I'll look at them every now and then, but there is no good reason at this point for me to be expecting them to fail unless I do something stupid (lol, and that is ALWAYS a possibility

). I think XViper would agree, becasue the kind of shifting he's talking about constitutes abuse.

). I think XViper would agree, becasue the kind of shifting he's talking about constitutes abuse.As for the beeper, it just looks to me like the thing sometimes picks up a burst of noise from somewhere. It doesn't affect the operation of the beeper itself, and the RPM memory function is still useful.

The first time I read over 100k RPM from the memory my heart stopped for a second before I realized that the reading had to be bogus.

#75

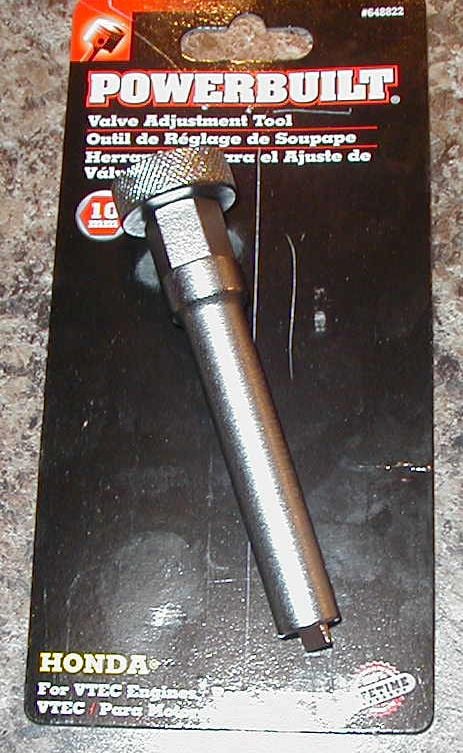

You bet I torque them nuts-14 foot pounds. It all started when I drove to another city to have the valves adjusted by a "super tuner". No torque wrench was used and when asked to check for cracked retainers he gave me a deer in the headlights look. So I bought the factory service manual (ebay) and the adustment tool and did it myself. The super tuner had most of the gaps to tight. This is not had hard to do. What takes me so long is I check and recheck and check it again. So I spent $110 for this but knowledge is not cheap. I did learn a cool trick for proping the hood up more so you had more room to work. Torque wrench is Sears clicky with .5 lbs increments.

#76

Moderator

Thread Starter

I do it like so:

Adjust clearance, snug locknut to about 15 n-m with special tool while holding screw.

Torque nut to 20 n-m with torque wrench.

Hand tighten to re-check, as I have a feel for how tight the nut should be. It will always move slightly.

ACCORDING to Honda, 20 n-m is correct. By my feel, it is about 21. I would imagine 20 is fine, as many have done it that way. A good torque wrench is key. S-K makes a real nice 3/8 drive.

Last step, check clearance.

Adjust clearance, snug locknut to about 15 n-m with special tool while holding screw.

Torque nut to 20 n-m with torque wrench.

Hand tighten to re-check, as I have a feel for how tight the nut should be. It will always move slightly.

ACCORDING to Honda, 20 n-m is correct. By my feel, it is about 21. I would imagine 20 is fine, as many have done it that way. A good torque wrench is key. S-K makes a real nice 3/8 drive.

Last step, check clearance.

#77

Registered User

i see what you're saying now...

essentially you do use a torque wrench.

your hand feel is the final check.

is there anything to do to help minimize the adjusting screw's movement when you tighten the bolt?

essentially you do use a torque wrench.

your hand feel is the final check.

is there anything to do to help minimize the adjusting screw's movement when you tighten the bolt?

#78

Registered User

Originally Posted by jyeung528,May 12 2007, 03:15 PM

is there anything to do to help minimize the adjusting screw's movement when you tighten the bolt?

I haven't done this nearly as many times as Billman, but I've done it enough that 3 out of 4 valves will be within 1-2 n-m of proper torque before I even pick up the torque wrench.

#79

Moderator

Thread Starter

Originally Posted by mxt_77,May 12 2007, 04:40 PM

Yeah, when you're snugging it up w/ the special too, get as close to 20n-m as possible. That way the nut won't move much to get to 20n-m, which means you won't risk the set screw moving much. But, you have to acquire the "feel" first.

I haven't done this nearly as many times as Billman, but I've done it enough that 3 out of 4 valves will be within 1-2 n-m of proper torque before I even pick up the torque wrench.

I haven't done this nearly as many times as Billman, but I've done it enough that 3 out of 4 valves will be within 1-2 n-m of proper torque before I even pick up the torque wrench.

#80

Registered User

Join Date: Feb 2004

Location: Dry Branch

Posts: 7,087

Likes: 0

Received 0 Likes

on

0 Posts

LOL, I haven't adjusted the valves on the MX5 even once in the 17 years we've owned the car, and it's nice to know I'll ever have to deal with it.

Of course the MX5 has non adjustable hydrolic lifters.

One of the things I like about buckets and hardened shims (AKA Fiat/Ferrari) or shims under hardened buckets (AKA Jaguar) is that all you usually have to do is verify the clearance. It rarely ever changes. Also, if you calculate the needed shim thickness correctly you get the calculated clearance and don't have to worry about it changing when you lock things down. It's too bad that VTEC is tied to rocker arms and screw adjusters.

Of course the MX5 has non adjustable hydrolic lifters.

One of the things I like about buckets and hardened shims (AKA Fiat/Ferrari) or shims under hardened buckets (AKA Jaguar) is that all you usually have to do is verify the clearance. It rarely ever changes. Also, if you calculate the needed shim thickness correctly you get the calculated clearance and don't have to worry about it changing when you lock things down. It's too bad that VTEC is tied to rocker arms and screw adjusters.