Brake Rotor question

#1

Hello All,

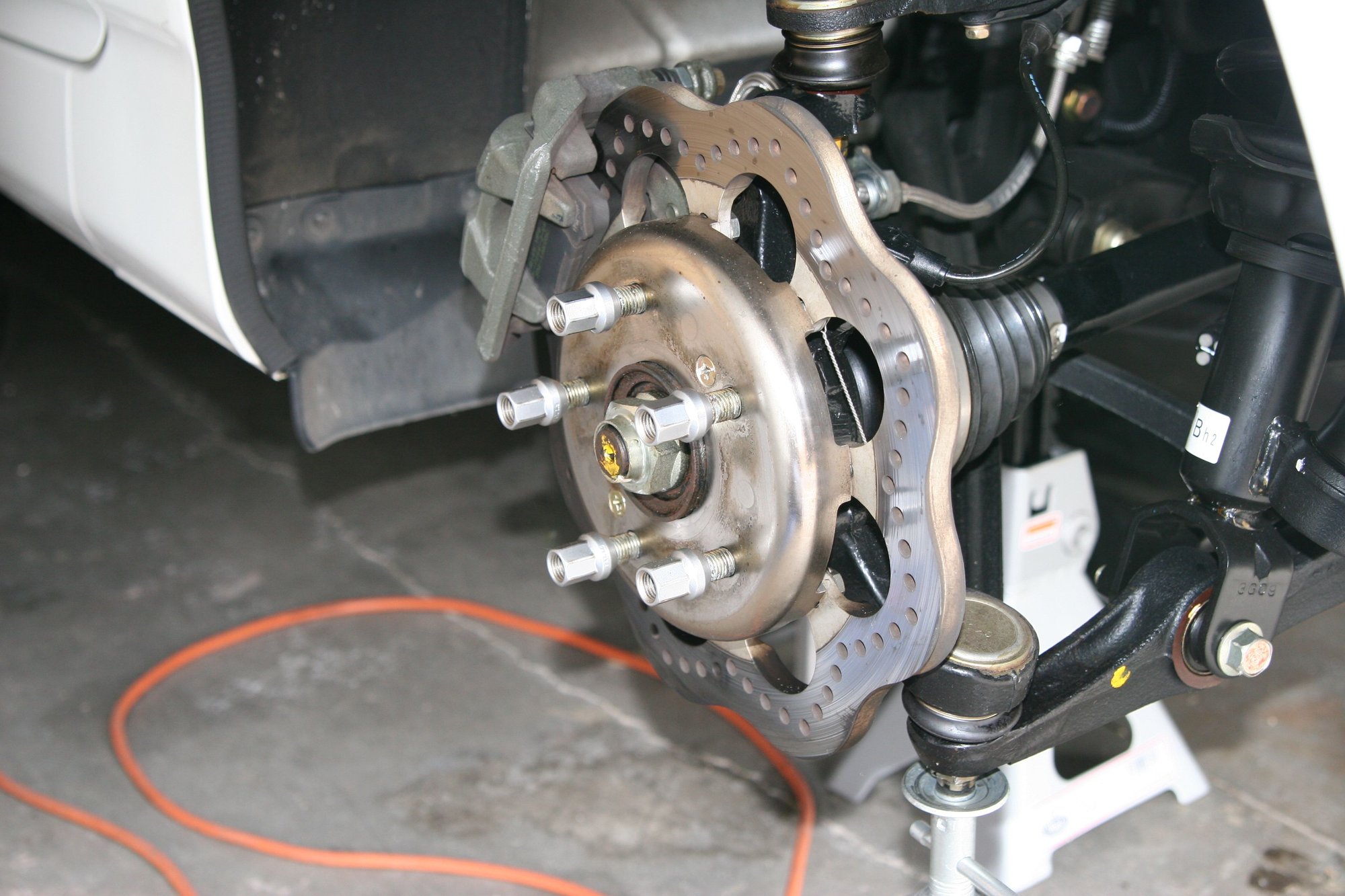

Kind've of a newbie question, but what's the difference between the OEM rotors vs. cross-drilled rotors vs. slotted rotors vs. drilled/slotted rotors? Is one better than another in terms of longevitity? My Sk2 is a daily driver and figure that having better stopping power won't hurt but I don't want to compromise the longevitity too much.

Any suggestions/advice is welcome.

D'Andre

Kind've of a newbie question, but what's the difference between the OEM rotors vs. cross-drilled rotors vs. slotted rotors vs. drilled/slotted rotors? Is one better than another in terms of longevitity? My Sk2 is a daily driver and figure that having better stopping power won't hurt but I don't want to compromise the longevitity too much.

Any suggestions/advice is welcome.

D'Andre

#2

try reading this, it's got all the info you need

https://www.s2ki.com/forums/index.php?showt...0&#entry8804747

https://www.s2ki.com/forums/index.php?showt...0&#entry8804747

#3

Originally Posted by SupermanZ11,May 22 2007, 09:37 PM

Hello All,

Kind've of a newbie question, but what's the difference between the OEM rotors vs. cross-drilled rotors vs. slotted rotors vs. drilled/slotted rotors? Is one better than another in terms of longevitity? My Sk2 is a daily driver and figure that having better stopping power won't hurt but I don't want to compromise the longevitity too much.

Any suggestions/advice is welcome.

D'Andre

Kind've of a newbie question, but what's the difference between the OEM rotors vs. cross-drilled rotors vs. slotted rotors vs. drilled/slotted rotors? Is one better than another in terms of longevitity? My Sk2 is a daily driver and figure that having better stopping power won't hurt but I don't want to compromise the longevitity too much.

Any suggestions/advice is welcome.

D'Andre

Cross-drilled (modified) aftermarket OEM style rotors will eventually crack between the holes and fail due to the fact that a stress riser (where thermal and mechanical energies become focused) is created everywhere a hole is drilled through the cast iron. Additionally, the reduced surface area and mass actually reduce braking performance. Slotted rotors are less likely to crack than cross-drilled if the slot does not go from edge to edge (inner edge to outer edge).

Here's a good source of information on rotors:

http://www.thebrakeman.com/rotortech

The only time you should ever consider cross-drilled rotors is if the rotor's contact/friction material is steel, not cast iron.

Steel is much stronger than cast iron and resists cracking a great deal more. The reason for this is Steel's "grain" structure is not granular like iron castings. Steel has directional grain boundaries and bends in shear load conditions whereas castings crack or break.

The Brake Man's "Revolution" (wave rotor) design utilizes a two-piece rotor with a solid, cross-drilled friction portion, and a forged aluminum hat (center) portion. Their "Hurricane" rotors utilize a vented, laminated steel friction material (with slots) with the same forged aluminum hat section as the wave rotor. http://www.thebrakeman.com/products .

I have the Hurricane rotors up front, and the wave rotors in the rear on my S2000. I use their tornado calipers, and SS brake lines (with residual valves on the front lines). They're not cheap, but worth every penny. I use Hawk HPS pads specifically designed for the Tornado calipers.

A point of note for two-piece rotors: It's critical the "hat" portion be made from a material other than standard "billet" or cast aluminum. If aluminum is used in the hat section, ensure it's forged aluminum. Forged aluminum is several times stronger than cast (or non-forged, billet aluminum) - especially when it's heated. The strength of cast or standard billet aluminum decreases greatly as it heats up. Depending on the alloy, machined billet and cast aluminum have strengths from 18-35 ksi at 70F, that decrease to as low as 6-12 ksi at temps as "low" as 600F - the friction portion of the rotor can achieve 1000+F during track days! Considering the 'hat' it bolted directly to the hottest part of your braking system, it only makes sense you don't want a material that gets weak when things get hot! Forged aluminum retains strengths of approximately 40-70 ksi at peak braking temperatures (alloy dependent).

Too many aftermarket kits offer two-piece rotors using weak, billet hats. In fact, a penny-pinching member of this site found out the problems associated with using inferior rotors - the hard way! He bought a set of Brake Man calipers from Rick's site a few years back, but didn't want to pay the price for the Brake Man rotors and hats. He used an inferior set of rotors utilizing billet hats - which failed (sheared where the hat bolted to the rotor) during a track day. To this day, his ego has not let him admit to his bad decision - he blames the Brake Man calipers for the failure! So much for learning from your mistakes.

BTW - I'm not affiliated with Brake Man in any way - other than owning and loving the set on my car!

#5

Originally Posted by 6speedftw,May 23 2007, 01:15 AM

try reading this, it's got all the info you need

https://www.s2ki.com/forums/index.php?showt...0&#entry8804747

https://www.s2ki.com/forums/index.php?showt...0&#entry8804747

Thread

Thread Starter

Forum

Replies

Last Post