Urge / Endyn engine failure

#211

Member

Thread Starter

The crank was balance checked by Rolls Royce automotive's engine balance machine shop. The company who rebuilt the engine build many of the controlled race engines for the UK race series, so I'm sure they can check the run out on the crank. Mahle's F1 guy inspected the bearings and was amazed at the damage.

The manifold was made by Urge / Endyn. It's a custom plenum with OEM runners. The walls have been thinned quite a lot so it's going to lose strength.

It already had a repair on runner 1 when I received the engine from Urge so clearly it was a known issue. Looks like a fatigue crack.

Link doesn't work?

Edit - found it.

The manifold was made by Urge / Endyn. It's a custom plenum with OEM runners. The walls have been thinned quite a lot so it's going to lose strength.

It already had a repair on runner 1 when I received the engine from Urge so clearly it was a known issue. Looks like a fatigue crack.

Link doesn't work?

Edit - found it.

#212

I'm not attributing fault...and shipping damage is no one's fault.

The only part that was replaced was the crankshaft. The claim is the failure was do to balance. 4 cylinder engine are naturally in primary balance and the engine builder presented the balance sheet. It is highly unlikely the crank could have been out of balance or that a balance problem would have caused that issue. If it had that bad a balance problem it would have been pretty obvious.

The bearing damage was unusual...which is what makes this interesting. What exactly did the engine builder you went to say was the actual balance and straightness?

The only part that was replaced was the crankshaft. The claim is the failure was do to balance. 4 cylinder engine are naturally in primary balance and the engine builder presented the balance sheet. It is highly unlikely the crank could have been out of balance or that a balance problem would have caused that issue. If it had that bad a balance problem it would have been pretty obvious.

The bearing damage was unusual...which is what makes this interesting. What exactly did the engine builder you went to say was the actual balance and straightness?

#213

Member

Thread Starter

Balance number is on the first page.

Straightness I didn't note down the measurement but he did check it like any engine builder would.

If it was bent, it was bent during initial build in my view. For it to bend inside the engine and see no external damage to the engine itself or the shipping box really rules that out. Along with theories about going over kerbs being the cause.

I'd also say a bent crank would exibit similar characteristics to an out of balance one, in that you'd have a 1x per rotation out of balance force.

But for the reasons above I am certain the crank itself was not bent or the builder would have said.

Straightness I didn't note down the measurement but he did check it like any engine builder would.

If it was bent, it was bent during initial build in my view. For it to bend inside the engine and see no external damage to the engine itself or the shipping box really rules that out. Along with theories about going over kerbs being the cause.

I'd also say a bent crank would exibit similar characteristics to an out of balance one, in that you'd have a 1x per rotation out of balance force.

But for the reasons above I am certain the crank itself was not bent or the builder would have said.

#214

There are lots of ways something can get a shock without external damage. It is why engines are often rebuilt after a wreck. Didn't you also have a cracked intake manifold? It looks like that was a fabricated manifold. Endyn works lots of little details...my guess is that welding was because they changed the shape. That probably made it the weak point...but it still took something to break it.

Endyn showed their balance info, and 4 cylinder engines are in primary balance regardless of bobweight.

Endyn showed their balance info, and 4 cylinder engines are in primary balance regardless of bobweight.

I call bullshit on motors being rebuilt after a wreck too. I've had my fair share of accidents and not once has my engine been replaced or rebuilt. Family and friends have been in some pretty good wrecks too and the motors never get rebuilt.

There was something wrong with the build on this motor. Either there was a harmonic issue with the crank or the bearing clearance was bad on the main bearings. I would lean more to a harmonic issue due to the intake manifold cracking, which from the pictures appears to have been repaired a few times.

#215

The crank in this car can hold many times the factory amount of horse power, and you are trying to tell us that a slight jar or shaking during shipping will bend the hardened steel crank and not break the aluminum main bearing caps? Get real. If you bent a crank during shipping, there would be other issues that would be more pressing.

I call bullshit on motors being rebuilt after a wreck too. I've had my fair share of accidents and not once has my engine been replaced or rebuilt. Family and friends have been in some pretty good wrecks too and the motors never get rebuilt.

There was something wrong with the build on this motor. Either there was a harmonic issue with the crank or the bearing clearance was bad on the main bearings. I would lean more to a harmonic issue due to the intake manifold cracking, which from the pictures appears to have been repaired a few times.

I call bullshit on motors being rebuilt after a wreck too. I've had my fair share of accidents and not once has my engine been replaced or rebuilt. Family and friends have been in some pretty good wrecks too and the motors never get rebuilt.

There was something wrong with the build on this motor. Either there was a harmonic issue with the crank or the bearing clearance was bad on the main bearings. I would lean more to a harmonic issue due to the intake manifold cracking, which from the pictures appears to have been repaired a few times.

Sad to see this thread pop up again, but good to hear it's back up and running.

I feel for MB. Having s**t results with Endyn over a decade ago, this is nothing new.

I feel for MB. Having s**t results with Endyn over a decade ago, this is nothing new.It's hard to say exactly what the culprit is, but it could have been a multitude of things. I'd point to bearing clearances being at least one of the culprits as the thing failed in VERY short order. Also, Urge and Endyn severing ties tells me something went wrong. Patrick at Urge seems to try to please his customers (haven't dealt w/ him personally), and I can only assume he came to realize Larry isn't the super master he claims to be and cut the anchor loose. Smart move.

#216

Sad to see this thread pop up again, but good to hear it's back up and running.

I feel for MB. Having s**t results with Endyn over a decade ago, this is nothing new.

I feel for MB. Having s**t results with Endyn over a decade ago, this is nothing new.It's hard to say exactly what the culprit is, but it could have been a multitude of things. I'd point to bearing clearances being at least one of the culprits as the thing failed in VERY short order. Also, Urge and Endyn severing ties tells me something went wrong. Patrick at Urge seems to try to please his customers (haven't dealt w/ him personally), and I can only assume he came to realize Larry isn't the super master he claims to be and cut the anchor loose. Smart move.

I also didn't want to mention, mostly because I don't actually know, but how much R&D was spent by Endyn/Urge to make these "race" motors reliable. I mean they aren't exactly a Cosworth or other large corporation that can throw vast sums of money to R&D and test. You can see it in how long Urge takes to get a product to market, (I'm not saying that as a bad thing.....they are small and have to take their time to get things right).

#217

Originally Posted by 06Estukay' timestamp='1417795211' post='23427916

MB, can you elaborate as to why your engine builder ditched the Fluidampr?

I agree, however, that goes for a STOCK internals motor.

Originally Posted by Bullwings' timestamp='1418354694' post='23434755

That said, I won't ever build my motor. OEM FTW. KISS.

#219

Balance number is on the first page.

Straightness I didn't note down the measurement but he did check it like any engine builder would.

If it was bent, it was bent during initial build in my view. For it to bend inside the engine and see no external damage to the engine itself or the shipping box really rules that out. Along with theories about going over kerbs being the cause.

I'd also say a bent crank would exibit similar characteristics to an out of balance one, in that you'd have a 1x per rotation out of balance force.

But for the reasons above I am certain the crank itself was not bent or the builder would have said.

Straightness I didn't note down the measurement but he did check it like any engine builder would.

If it was bent, it was bent during initial build in my view. For it to bend inside the engine and see no external damage to the engine itself or the shipping box really rules that out. Along with theories about going over kerbs being the cause.

I'd also say a bent crank would exibit similar characteristics to an out of balance one, in that you'd have a 1x per rotation out of balance force.

But for the reasons above I am certain the crank itself was not bent or the builder would have said.

The counterweights are used to minimize stresses and bending within the crank by offsetting each throw individually. It won't show in a balance as the counterweights will offset each other and the rod journal throws will offset each other. Note that an underlying problem with the high RPM and the larger displacement Honda engines is the low or zero overlap of the main and rod journals. It makes the crank weaker and is discussed in some of the 2.4L engine discussions here.

Balance is specified in oz-in or gm-mm left and right. The measurement is just taken at the ends of the crank. "318gm @ 27 degrees" is the correction for a specific (and in this case unspecified) radius where the adjustment is made. Most of the shop balancers will translate that to where hand how deep a whole to drill (bit diameter is specified by the machinist for the width of the counterweights or how much mallory to add. They also have the option of multiple holes. Lots of racing engine builders take the weight off the side of the counterweight rather than drill on the end because of windage concerns; power spent throwing oil around inside the engine is power not going to the rear wheels.

Endyn showed the balance info from a CWT balancer. It showed very, very tight balance, far more than is necessary. CWT has an hour long set of 6 videos on their balancer; this is the link to the first: https://www.youtube....h?v=d9DZzrpjc5Y. Given that they turned it in a lathe rather than drill holes which can be done on the balancing machine, the engine builder (Endyn) must have had a very good sense of how to balance this crank. If you don't agree, try a little static balancing experiment where you add weight by eye.

I wouldn't be surprised if your shop left a weight off one of his bobweights and didn't recheck because he was scrapping the crank.

Dropping reciprocating weight is very important on a high rpm 4 cylinder. The reason is secondary balance. The only ways to affect it are balance shafts, reciprocating weight, and rod and stroke length. Constraints are rules and cost, both initial and ongoing maintenance (really light stuff doesn't last forever). Where the rules involved in the original order requiring a stock crank and rods? I like billet cranks and rods, which really aren't that much more expensive. But even at $10k+, the extra $1000-$1500 for a billet crank and maybe $300-$500 for lightweight rods (over the cost for standard billet rods) maybe out of budget.

The block looked like it had Darton sleeves. Does this engine have a big 90mm bore? I don't think you ever provided bore/stroke, compression, and cam timing info.

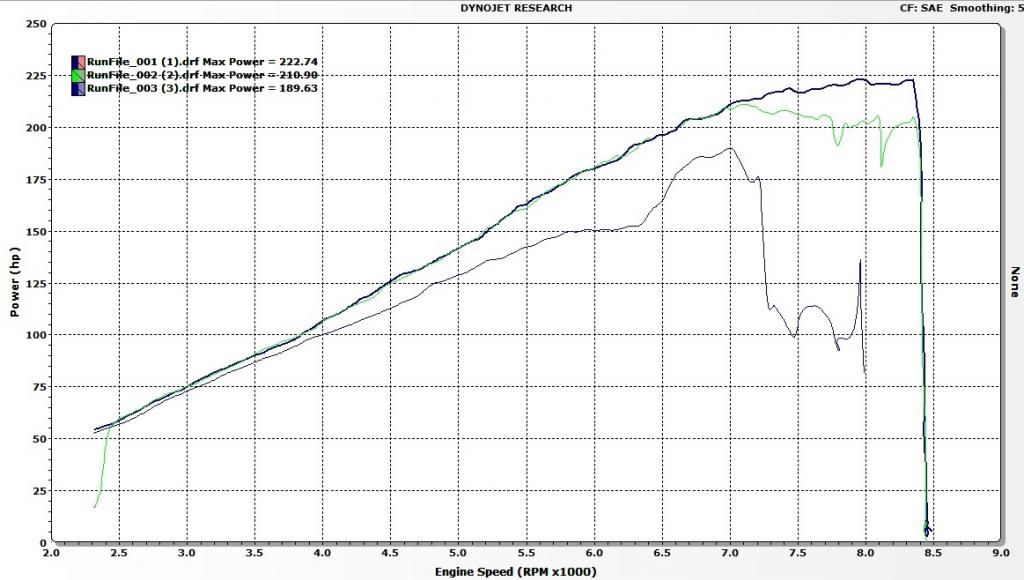

Which brings up the next issue: running a 9500rpm engine at 8500rpm loses a lot of power on the track. It can make sense as a tradeoff when the engine has a large displacement (2.4+L) where the trade off also provides a wider powerband and allows less expensive components. However, if the dyno run on the first page is this engine, it seems the head, cam, intake, and exhaust are setup for 9500rpm on that displacement. It held its power peak for 500 rpm through 9000 and at 9500 it still had as much power as it did at 7100. Unless you have very, very close gearing or are running on the high banks of Daytona loosing those rpm will put you into a much lower part of the powerband with a lot less HP.

#220

The oil level was not low enough for the pickup tube to become uncovered in addition to lack of G forces don't allow oil to pool anywhere. If being roughly half a quart low on oil caused oil starvation, anyone who tracks would spin bearings regularly with the oil level right up to the top.

I have a friend that intentionally ran his oil level low to prevent it from being sucked up into the intake. He also got low enough to lose VTEC operation once. He came off track, topped it off and went back out. When he came to my local track, he was a tenth or so of the class lap record on his first session out on the track, ever, with 225 R-comps that were heat cycled out. That car saw so much abuse between all the codriving at autoX and track events, it was unreal. He sold it last year to someone else who tracks it still.