how high can you safely rev a stock F20c?

#12

I can rev my F20C up to 10,500 rpm. But with Hondata K-Pro and other Sensors.

The crank-sensor and the camshaft-TDC-Sensor is different than stock. They have to be changed when going with K-Pro.

My previous post was mechanical related. But the infos about the stock-Ecu are very interesting! A very fast ECU like Bosch Motronic MS5 Family must be very effective for releasing some power at high rpm's.

Maybe the decreasing power at higher engine speeds beginning from 8,000 rpm is related to the limited capacities of the sensors and the cpu inside the ECU.

Interesting, interesting.....

The crank-sensor and the camshaft-TDC-Sensor is different than stock. They have to be changed when going with K-Pro.

My previous post was mechanical related. But the infos about the stock-Ecu are very interesting! A very fast ECU like Bosch Motronic MS5 Family must be very effective for releasing some power at high rpm's.

Maybe the decreasing power at higher engine speeds beginning from 8,000 rpm is related to the limited capacities of the sensors and the cpu inside the ECU.

Interesting, interesting.....

#13

Banned

the stock ecu doesnt have any issues calculating the actual rpm.

there is this thing called inertia.. it is not uncommon for an engine to go a few hundred rpms over the limiter. All the ecu does is shut off fuel or spark, neither of which actually completely stop the engine, just stop it from accelerating more.

if you search here you will see a number of stock f22 motors that lost a rod going over 9k rpms. IMHO the big end of the rod isnt strong enough to maintain rpms that high. The big end will get out of round and eventually break a rod bolt, break the rod itself or spin a bearing.

the ecu has the ability to anticipate where the next crank tooth will be based on when it saw the previous one.

how do you think Mitsubishi motors work at high rpm, they only have 4 crank teeth.

the custom crank triggers we use on b and h series engines run 12 teeth and have no problem at 11k rpms, OE s2000 stuff has more than enough teeth on the crank trigger to maintain accuracy at very high rpms.

there is this thing called inertia.. it is not uncommon for an engine to go a few hundred rpms over the limiter. All the ecu does is shut off fuel or spark, neither of which actually completely stop the engine, just stop it from accelerating more.

if you search here you will see a number of stock f22 motors that lost a rod going over 9k rpms. IMHO the big end of the rod isnt strong enough to maintain rpms that high. The big end will get out of round and eventually break a rod bolt, break the rod itself or spin a bearing.

the ecu has the ability to anticipate where the next crank tooth will be based on when it saw the previous one.

how do you think Mitsubishi motors work at high rpm, they only have 4 crank teeth.

the custom crank triggers we use on b and h series engines run 12 teeth and have no problem at 11k rpms, OE s2000 stuff has more than enough teeth on the crank trigger to maintain accuracy at very high rpms.

#14

Inertia can NOT cause the engine to continue accellerating after fuel cut. Inertia is the resistence to accelleration / decelleration. If fuel is truly cut, the crank (and car) will instantly start decellerating.

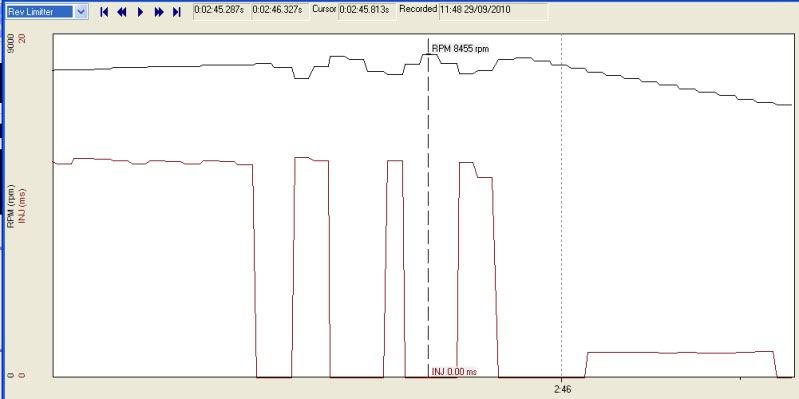

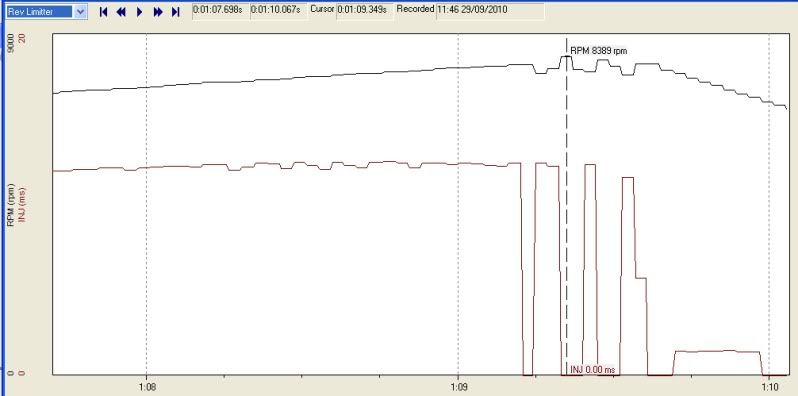

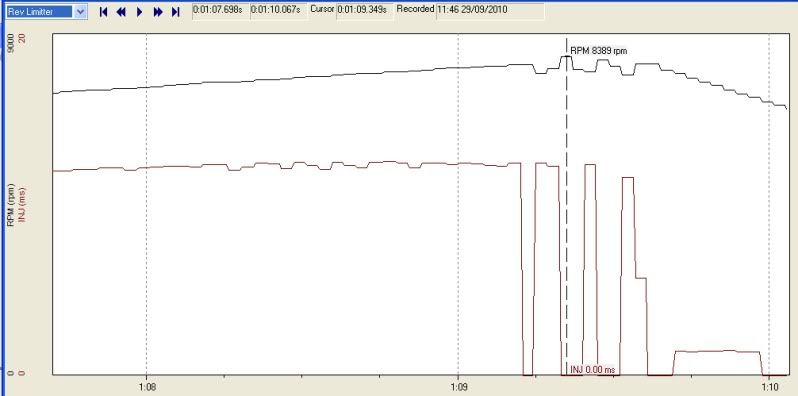

Here is a 2 second snapshot of my brother's 100% stock '06 as it hits the rev limitter in 3rd gear. The purple line is the fuel injector pulse width. I could only select 1 spot on the datalog, so here is the sequence of RPMs as it hits the rev limitter:

RPM ... Inj. PW

8169 12.4

8178 0

7936 12.39

8081 12.22

8389 0

8047 0

7978 12.3

8305 0

8125 0

7903 11.6

8196 5.68

Here is a 2 second snapshot of my brother's 100% stock '06 as it hits the rev limitter in 3rd gear. The purple line is the fuel injector pulse width. I could only select 1 spot on the datalog, so here is the sequence of RPMs as it hits the rev limitter:

RPM ... Inj. PW

8169 12.4

8178 0

7936 12.39

8081 12.22

8389 0

8047 0

7978 12.3

8305 0

8125 0

7903 11.6

8196 5.68

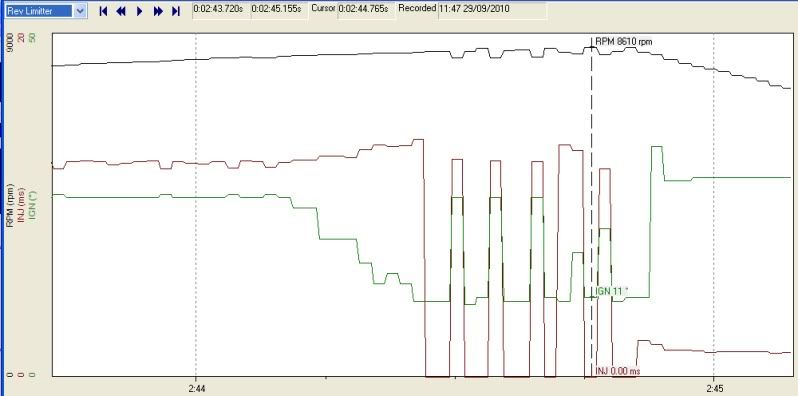

#16

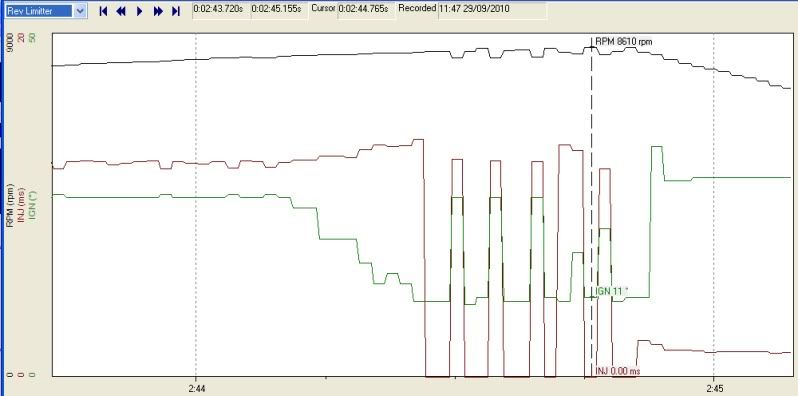

Here is how my rev limitter is with my current tune. I took Hondata's advice, and retarded ignition timing quite a bit for the last 100 RPMs (8400+). This really softens the rev limiter a lot. I'm now just overshooting the 8500 RPM rev limit by 110 RPMs, as opposed to 255 RPMs with the stock tune. So even though I've technically raised the rev limit by 300 RPM's I'm really only going 150 RPMs higher than the stock tune allows.

BTW, I added the green line, which is ignition timing. You can see how it retards quickly as it approaches 8500.

BTW, I added the green line, which is ignition timing. You can see how it retards quickly as it approaches 8500.

#17

Just a few calculations for the discussion:

at 8,000rpm the time for one complete revolution of the crank is 7.5ms (milliseconds).

The Intake valve opens 50 degrees before TDC and closes 65 degrees after BDC. This is 295 degrees in crank angle and means that at 8,000rpm the intake valve is open for 6.15ms.

I looked in my datalogs and at 8,000 rpm my F20c with stock injectors and fuel pressure is spraying nearly 10ms. Considering injector delay times, it could be that the effective open time for the injectors is at the border of effectiveness.

The same calculation for 10,000 rpm shows that there's only 4.9ms time for spraying fuel into the cylinder.

And yes, there is the possibilty of spraying before the valve opens, but there's no longitudinal airflow inside the manifold so that the pre-injected fuel is not fully atomized.

Could raising the fuel pressure at higher rpms help to release more power due to better fuel-air-mixture distribution?

at 8,000rpm the time for one complete revolution of the crank is 7.5ms (milliseconds).

The Intake valve opens 50 degrees before TDC and closes 65 degrees after BDC. This is 295 degrees in crank angle and means that at 8,000rpm the intake valve is open for 6.15ms.

I looked in my datalogs and at 8,000 rpm my F20c with stock injectors and fuel pressure is spraying nearly 10ms. Considering injector delay times, it could be that the effective open time for the injectors is at the border of effectiveness.

The same calculation for 10,000 rpm shows that there's only 4.9ms time for spraying fuel into the cylinder.

And yes, there is the possibilty of spraying before the valve opens, but there's no longitudinal airflow inside the manifold so that the pre-injected fuel is not fully atomized.

Could raising the fuel pressure at higher rpms help to release more power due to better fuel-air-mixture distribution?

#18

Banned

I have tested that...

we put 1000cc injectors in a 180hp NA car and fully tuned the injector timing to keep from spraying fuel on the back of the valve and compared that to the stock 240cc injectors.

there was no real difference in performance.

pretty much you will always be spraying fuel on the back of the intake valves. the heat of the valve helps atomize the fuel and the fuel helps cool the valve.

basically, it doesnt matter.. lol

we put 1000cc injectors in a 180hp NA car and fully tuned the injector timing to keep from spraying fuel on the back of the valve and compared that to the stock 240cc injectors.

there was no real difference in performance.

pretty much you will always be spraying fuel on the back of the intake valves. the heat of the valve helps atomize the fuel and the fuel helps cool the valve.

basically, it doesnt matter.. lol

#19

I've read different from others:

From an german engineering article.

Makes sense for me, because even when a part of the fuel is vaporized at the valve, a lot of fuel is condensed at the manifold walls, where only a part of it is ripped of by the air flow. The time is to short at high rpms. A reason why direct injection is so efficient.

"...The next step was a variation of the injection timing. A default value of the injection end at 360° crank angle before ignition top dead centre appeared not to be optimal, because around 230° crank angle the torque was 5 to 7 % higher than before..."

Makes sense for me, because even when a part of the fuel is vaporized at the valve, a lot of fuel is condensed at the manifold walls, where only a part of it is ripped of by the air flow. The time is to short at high rpms. A reason why direct injection is so efficient.

#20

Originally Posted by bpaspi,Oct 26 2010, 02:30 PM

at 8,000rpm the time for one complete revolution of the crank is 7.5ms (milliseconds).

The Intake valve opens 50 degrees before TDC and closes 65 degrees after BDC. This is 295 degrees in crank angle and means that at 8,000rpm the intake valve is open for 6.15ms.

The Intake valve opens 50 degrees before TDC and closes 65 degrees after BDC. This is 295 degrees in crank angle and means that at 8,000rpm the intake valve is open for 6.15ms.

That said, I did pick up high power in the upper RPMs by replacing my OEM injectors with Siemens 630cc injectors. I have a basic I/H/E build, and my stock injectors were going past 90% duty. It is at 45% duty now, so if your numbers above are correct, then I guess they could be spraying only while the valves are open.