From 375whp Turbo S2k.. Boom...to: built LS6 with a bunch of goodies !

#401

Registered User

Thread Starter

Join Date: Jul 2012

Posts: 1,146

Likes: 0

Received 0 Likes

on

0 Posts

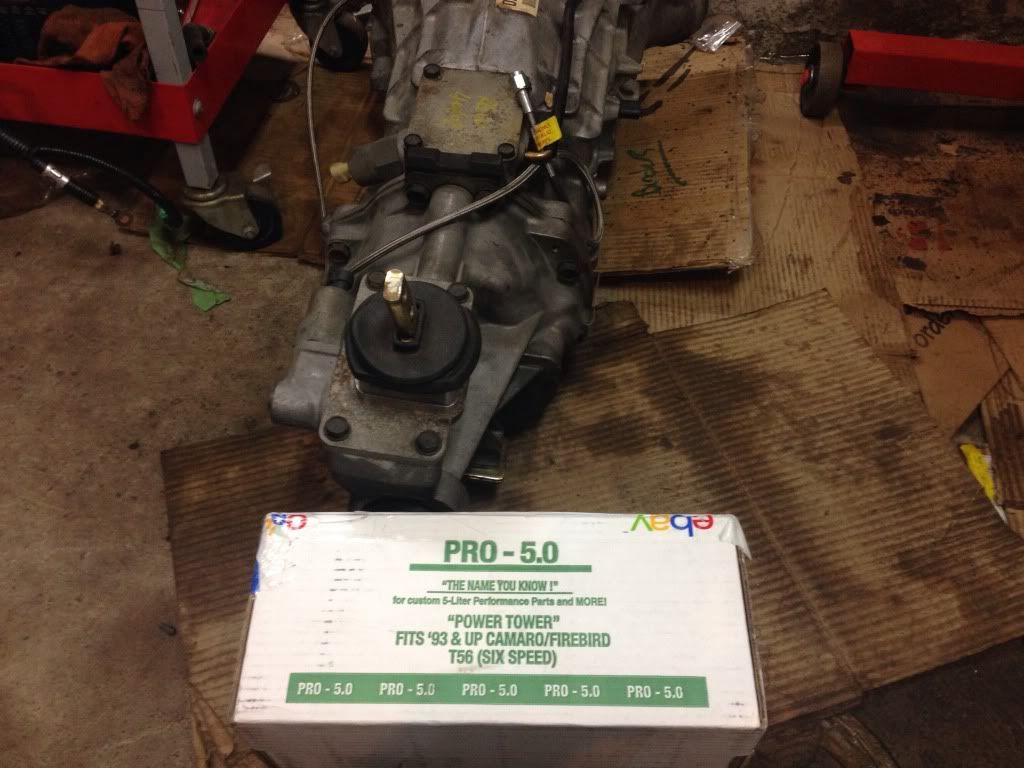

so i finally got some more parts in and am slowly starting to get ready to kick it into high gear !!

pics !!

first I cut the subframe up to make taking my long tube headers in and out that much easier... this was my choice I did not have to cut away this much but I did, cut and boxed back in for structural support !

pics !!

first I cut the subframe up to make taking my long tube headers in and out that much easier... this was my choice I did not have to cut away this much but I did, cut and boxed back in for structural support !

#402

Registered User

Thread Starter

Join Date: Jul 2012

Posts: 1,146

Likes: 0

Received 0 Likes

on

0 Posts

#403

Registered User

Thread Starter

Join Date: Jul 2012

Posts: 1,146

Likes: 0

Received 0 Likes

on

0 Posts

#406

Registered User

Thread Starter

Join Date: Jul 2012

Posts: 1,146

Likes: 0

Received 0 Likes

on

0 Posts

Thanks guys !!

Kyle, welding...... Many years but 95% on exhaust where the steel wall thickness is much greater. This was my first time welding thin thin sheet metal to a thick object, it was hard to not blow through the thin while heating up the thick enough to get penetration. I found it easiest to just do tacks 1/2" apart all the way along then fill it in after, that's why it looks so uneven, but it didn't matter because then I just ground it down fairly even anyways.

Kyle, welding...... Many years but 95% on exhaust where the steel wall thickness is much greater. This was my first time welding thin thin sheet metal to a thick object, it was hard to not blow through the thin while heating up the thick enough to get penetration. I found it easiest to just do tacks 1/2" apart all the way along then fill it in after, that's why it looks so uneven, but it didn't matter because then I just ground it down fairly even anyways.

#408

Registered User

Thread Starter

Join Date: Jul 2012

Posts: 1,146

Likes: 0

Received 0 Likes

on

0 Posts

It will need to come in and out a couple of times, watch the reverse switch on the trans I broke mine off first time haha. Hammer the tunnel back it will need quite a massage.