PTUNING S2000 Turbo System (Pics, Dyno, Pricing)

#2261

Ok, this is for Andrew and Mr C and others at Ptuning. I think the entire Ptuning community would like a definitive answer to the oil restrictor question for your supplied garrett turbos. Please read this thread that Andrew has commented on a few times:

https://www.s2ki.com/s2000/topic/958...rrett-warranty

This is directly from the garrett website.

Does my turbo require an oil restrictor?

A. Oil requirements depend on the turbo's bearing system type. Garrett has two types of bearing systems; traditional journal bearing; and ball bearing. The journal bearing system in a turbo functions very similarly to the rod or crank bearings in an engine. These bearings require enough oil pressure to keep the components separated by a hydrodynamic film. If the oil pressure is too low, the metal components will come in contact causing premature wear and ultimately failure. If the oil pressure is too high, leakage may occur from the turbocharger seals. With that as background, an oil restrictor is generally not needed for a journal-bearing turbocharger except for those applications with oil-pressure-induced seal leakage. Remember to address all other potential causes of leakage first (e.g., inadequate/improper oil drain out of the turbocharger, excessive crankcase pressure, turbocharger past its useful service life, etc.) and use a restrictor as a last resort. Garrett distributors can tell you the recommended range of acceptable oil pressures for your particular turbo. Restrictor size will always depend on how much oil pressure your engine is generating-there is no single restrictor size suited for all engines. Ball-bearing turbochargers can benefit from the addition of an oil restrictor, as most engines deliver more pressure than a ball bearing turbo requires. The benefit is seen in improved boost response due to less windage of oil in the bearing. In addition, lower oil flow further reduces the risk of oil leakage compared to journal-bearing turbochargers. Oil pressure entering a ball-bearing turbocharger needs to be between 40 psi and 45 psi at the maximum engine operating speed. For many common passenger vehicle engines, this generally translates into a restrictor with a minimum of 0.040" diameter orifice upstream of the oil inlet on the turbocharger center section. Again, it is imperative that the restrictor be sized according to the oil pressure characteristics of the engine to which the turbo is attached. Always verify that the appropriate oil pressure is reaching the turbo. The use of an oil restrictor can (but not always) help ensure that you have the proper oil flow/pressure entering the turbocharger, as well as extract the maximum performance.

I had issues with a precision turbo smoking because their internal restrictor was not sufficient and I had to add a 0.035 restrictor to make turbo stop smoking. We all know this engine has very high oil pressure and from Garrett website they say to keep oil pressure between 40-45psi. Is there a restrictor on the supplied turbo from Garrett designed to keep oil pressure in the correct range for our car? I have a feeling that is not the case. Do we need an external restrictor 0.035 to keep oil pressures at recommended levels for our car? I as others would like a definitive answer to this question immediately so that we can take the necessary precautions so that we do not blow our turbos due to improper installation, which includes no restrictor.

Your prompt reply and why you feel that way, backed up with some data would be appreciated.

https://www.s2ki.com/s2000/topic/958...rrett-warranty

This is directly from the garrett website.

Does my turbo require an oil restrictor?

A. Oil requirements depend on the turbo's bearing system type. Garrett has two types of bearing systems; traditional journal bearing; and ball bearing. The journal bearing system in a turbo functions very similarly to the rod or crank bearings in an engine. These bearings require enough oil pressure to keep the components separated by a hydrodynamic film. If the oil pressure is too low, the metal components will come in contact causing premature wear and ultimately failure. If the oil pressure is too high, leakage may occur from the turbocharger seals. With that as background, an oil restrictor is generally not needed for a journal-bearing turbocharger except for those applications with oil-pressure-induced seal leakage. Remember to address all other potential causes of leakage first (e.g., inadequate/improper oil drain out of the turbocharger, excessive crankcase pressure, turbocharger past its useful service life, etc.) and use a restrictor as a last resort. Garrett distributors can tell you the recommended range of acceptable oil pressures for your particular turbo. Restrictor size will always depend on how much oil pressure your engine is generating-there is no single restrictor size suited for all engines. Ball-bearing turbochargers can benefit from the addition of an oil restrictor, as most engines deliver more pressure than a ball bearing turbo requires. The benefit is seen in improved boost response due to less windage of oil in the bearing. In addition, lower oil flow further reduces the risk of oil leakage compared to journal-bearing turbochargers. Oil pressure entering a ball-bearing turbocharger needs to be between 40 psi and 45 psi at the maximum engine operating speed. For many common passenger vehicle engines, this generally translates into a restrictor with a minimum of 0.040" diameter orifice upstream of the oil inlet on the turbocharger center section. Again, it is imperative that the restrictor be sized according to the oil pressure characteristics of the engine to which the turbo is attached. Always verify that the appropriate oil pressure is reaching the turbo. The use of an oil restrictor can (but not always) help ensure that you have the proper oil flow/pressure entering the turbocharger, as well as extract the maximum performance.

I had issues with a precision turbo smoking because their internal restrictor was not sufficient and I had to add a 0.035 restrictor to make turbo stop smoking. We all know this engine has very high oil pressure and from Garrett website they say to keep oil pressure between 40-45psi. Is there a restrictor on the supplied turbo from Garrett designed to keep oil pressure in the correct range for our car? I have a feeling that is not the case. Do we need an external restrictor 0.035 to keep oil pressures at recommended levels for our car? I as others would like a definitive answer to this question immediately so that we can take the necessary precautions so that we do not blow our turbos due to improper installation, which includes no restrictor.

Your prompt reply and why you feel that way, backed up with some data would be appreciated.

Hello S2000442, and anyone else watching this thread.

The following post is in regards to the oil restrictor question pertaining to PTUNING turbo kits ONLY. Running the following Garrett turbo's

GT-3076

GTX-3076

GT-3582

GTX-3582

GTX-3576

We run and supply every PTUNING S2k kit with a 0.035" Restrictor.

Pictures below

Oil pressure entering a ball-bearing turbocharger needs to be between 40 psi and 45 psi at the maximum engine operating speed. For many common passenger vehicle engines, this generally translates into a restrictor with a minimum of 0.040" diameter orifice upstream of the oil inlet on the turbocharger center section.

For the most part this does pertain to about 75% of all passenger vehicles today. However we found, that with the S2k's High RPM oil pressure we needed to utilize the smallest restrictor Garrett recommends for BB type turbo's. Which is why in turn we run a 0.035" over a 0.040" size restrictor.

I hope this helped answer some underlining questions. Thanks Drew

Oh and thanks for reply. This should clear up any questions some folks have asked about.

#2262

[/quote]

So this was supplied and we needed to add it to the turbo first and then hook up the oil line? I will have to check my setup because I cannot remember from reading your install instructions. I assume it is clearly written in install instructions?

Oh and thanks for reply. This should clear up any questions some folks have asked about.

[/quote]

The restrictor comes pre-installed. It connects to the oil feed line.

So this was supplied and we needed to add it to the turbo first and then hook up the oil line? I will have to check my setup because I cannot remember from reading your install instructions. I assume it is clearly written in install instructions?

Oh and thanks for reply. This should clear up any questions some folks have asked about.

[/quote]

The restrictor comes pre-installed. It connects to the oil feed line.

#2264

Registered User

Join Date: Jan 2011

Location: PTUNING

Posts: 348

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by andrew@ptuning' timestamp='1340210588' post='21797305

Ok, this is for Andrew and Mr C and others at Ptuning. I think the entire Ptuning community would like a definitive answer to the oil restrictor question for your supplied garrett turbos. Please read this thread that Andrew has commented on a few times:

https://www.s2ki.com/s2000/topic/958...rrett-warranty

This is directly from the garrett website.

Does my turbo require an oil restrictor?

A. Oil requirements depend on the turbo's bearing system type. Garrett has two types of bearing systems; traditional journal bearing; and ball bearing. The journal bearing system in a turbo functions very similarly to the rod or crank bearings in an engine. These bearings require enough oil pressure to keep the components separated by a hydrodynamic film. If the oil pressure is too low, the metal components will come in contact causing premature wear and ultimately failure. If the oil pressure is too high, leakage may occur from the turbocharger seals. With that as background, an oil restrictor is generally not needed for a journal-bearing turbocharger except for those applications with oil-pressure-induced seal leakage. Remember to address all other potential causes of leakage first (e.g., inadequate/improper oil drain out of the turbocharger, excessive crankcase pressure, turbocharger past its useful service life, etc.) and use a restrictor as a last resort. Garrett distributors can tell you the recommended range of acceptable oil pressures for your particular turbo. Restrictor size will always depend on how much oil pressure your engine is generating-there is no single restrictor size suited for all engines. Ball-bearing turbochargers can benefit from the addition of an oil restrictor, as most engines deliver more pressure than a ball bearing turbo requires. The benefit is seen in improved boost response due to less windage of oil in the bearing. In addition, lower oil flow further reduces the risk of oil leakage compared to journal-bearing turbochargers. Oil pressure entering a ball-bearing turbocharger needs to be between 40 psi and 45 psi at the maximum engine operating speed. For many common passenger vehicle engines, this generally translates into a restrictor with a minimum of 0.040" diameter orifice upstream of the oil inlet on the turbocharger center section. Again, it is imperative that the restrictor be sized according to the oil pressure characteristics of the engine to which the turbo is attached. Always verify that the appropriate oil pressure is reaching the turbo. The use of an oil restrictor can (but not always) help ensure that you have the proper oil flow/pressure entering the turbocharger, as well as extract the maximum performance.

I had issues with a precision turbo smoking because their internal restrictor was not sufficient and I had to add a 0.035 restrictor to make turbo stop smoking. We all know this engine has very high oil pressure and from Garrett website they say to keep oil pressure between 40-45psi. Is there a restrictor on the supplied turbo from Garrett designed to keep oil pressure in the correct range for our car? I have a feeling that is not the case. Do we need an external restrictor 0.035 to keep oil pressures at recommended levels for our car? I as others would like a definitive answer to this question immediately so that we can take the necessary precautions so that we do not blow our turbos due to improper installation, which includes no restrictor.

Your prompt reply and why you feel that way, backed up with some data would be appreciated.

https://www.s2ki.com/s2000/topic/958...rrett-warranty

This is directly from the garrett website.

Does my turbo require an oil restrictor?

A. Oil requirements depend on the turbo's bearing system type. Garrett has two types of bearing systems; traditional journal bearing; and ball bearing. The journal bearing system in a turbo functions very similarly to the rod or crank bearings in an engine. These bearings require enough oil pressure to keep the components separated by a hydrodynamic film. If the oil pressure is too low, the metal components will come in contact causing premature wear and ultimately failure. If the oil pressure is too high, leakage may occur from the turbocharger seals. With that as background, an oil restrictor is generally not needed for a journal-bearing turbocharger except for those applications with oil-pressure-induced seal leakage. Remember to address all other potential causes of leakage first (e.g., inadequate/improper oil drain out of the turbocharger, excessive crankcase pressure, turbocharger past its useful service life, etc.) and use a restrictor as a last resort. Garrett distributors can tell you the recommended range of acceptable oil pressures for your particular turbo. Restrictor size will always depend on how much oil pressure your engine is generating-there is no single restrictor size suited for all engines. Ball-bearing turbochargers can benefit from the addition of an oil restrictor, as most engines deliver more pressure than a ball bearing turbo requires. The benefit is seen in improved boost response due to less windage of oil in the bearing. In addition, lower oil flow further reduces the risk of oil leakage compared to journal-bearing turbochargers. Oil pressure entering a ball-bearing turbocharger needs to be between 40 psi and 45 psi at the maximum engine operating speed. For many common passenger vehicle engines, this generally translates into a restrictor with a minimum of 0.040" diameter orifice upstream of the oil inlet on the turbocharger center section. Again, it is imperative that the restrictor be sized according to the oil pressure characteristics of the engine to which the turbo is attached. Always verify that the appropriate oil pressure is reaching the turbo. The use of an oil restrictor can (but not always) help ensure that you have the proper oil flow/pressure entering the turbocharger, as well as extract the maximum performance.

I had issues with a precision turbo smoking because their internal restrictor was not sufficient and I had to add a 0.035 restrictor to make turbo stop smoking. We all know this engine has very high oil pressure and from Garrett website they say to keep oil pressure between 40-45psi. Is there a restrictor on the supplied turbo from Garrett designed to keep oil pressure in the correct range for our car? I have a feeling that is not the case. Do we need an external restrictor 0.035 to keep oil pressures at recommended levels for our car? I as others would like a definitive answer to this question immediately so that we can take the necessary precautions so that we do not blow our turbos due to improper installation, which includes no restrictor.

Your prompt reply and why you feel that way, backed up with some data would be appreciated.

Hello S2000442, and anyone else watching this thread.

The following post is in regards to the oil restrictor question pertaining to PTUNING turbo kits ONLY. Running the following Garrett turbo's

GT-3076

GTX-3076

GT-3582

GTX-3582

GTX-3576

We run and supply every PTUNING S2k kit with a 0.035" Restrictor.

Pictures below

Oil pressure entering a ball-bearing turbocharger needs to be between 40 psi and 45 psi at the maximum engine operating speed. For many common passenger vehicle engines, this generally translates into a restrictor with a minimum of 0.040" diameter orifice upstream of the oil inlet on the turbocharger center section.

For the most part this does pertain to about 75% of all passenger vehicles today. However we found, that with the S2k's High RPM oil pressure we needed to utilize the smallest restrictor Garrett recommends for BB type turbo's. Which is why in turn we run a 0.035" over a 0.040" size restrictor.

I hope this helped answer some underlining questions. Thanks Drew

Oh and thanks for reply. This should clear up any questions some folks have asked about.

Yes the fittings is supplied with every PTUNING S2k kit.

Page 11of45 part #PTP-PKG-30000-10 has a picture of the restrictor fitting supplied with our kit. All though we ship the fitting already installed into the turbo CHRA. We complete that step for the customers.

file:///C:/Users/Andrew/Desktop/PTuning_Competition_S2000_Turbo_System_Installatio n_Manual_PTP-MAN-30000-Draft.pdf

#2266

Registered User

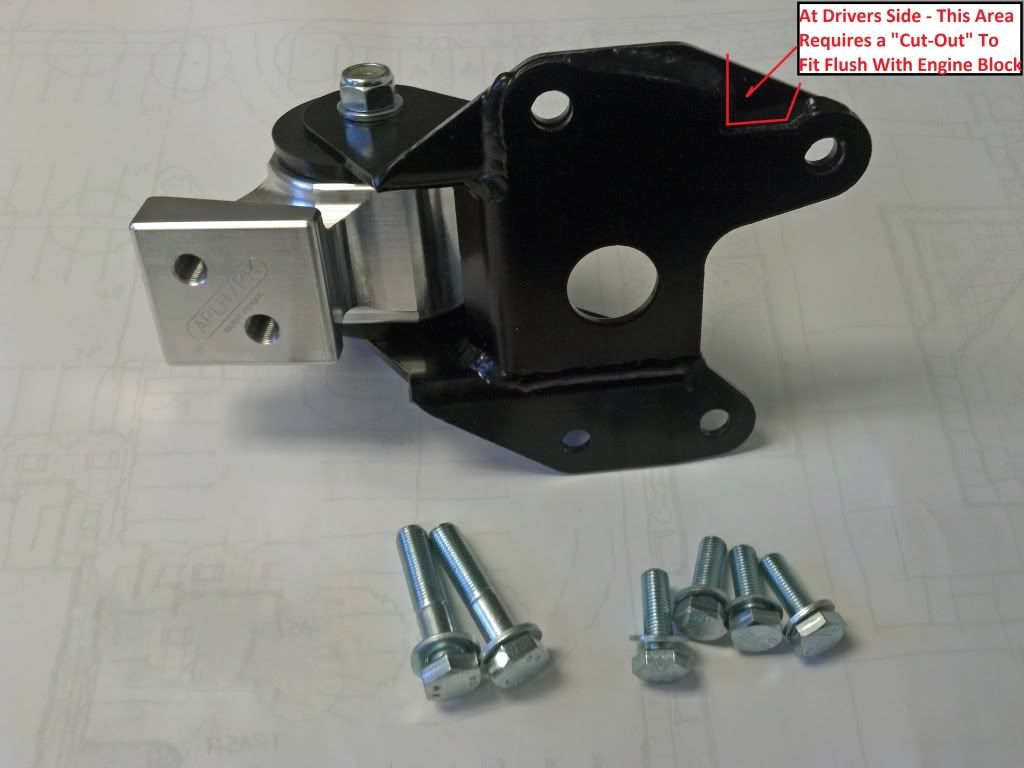

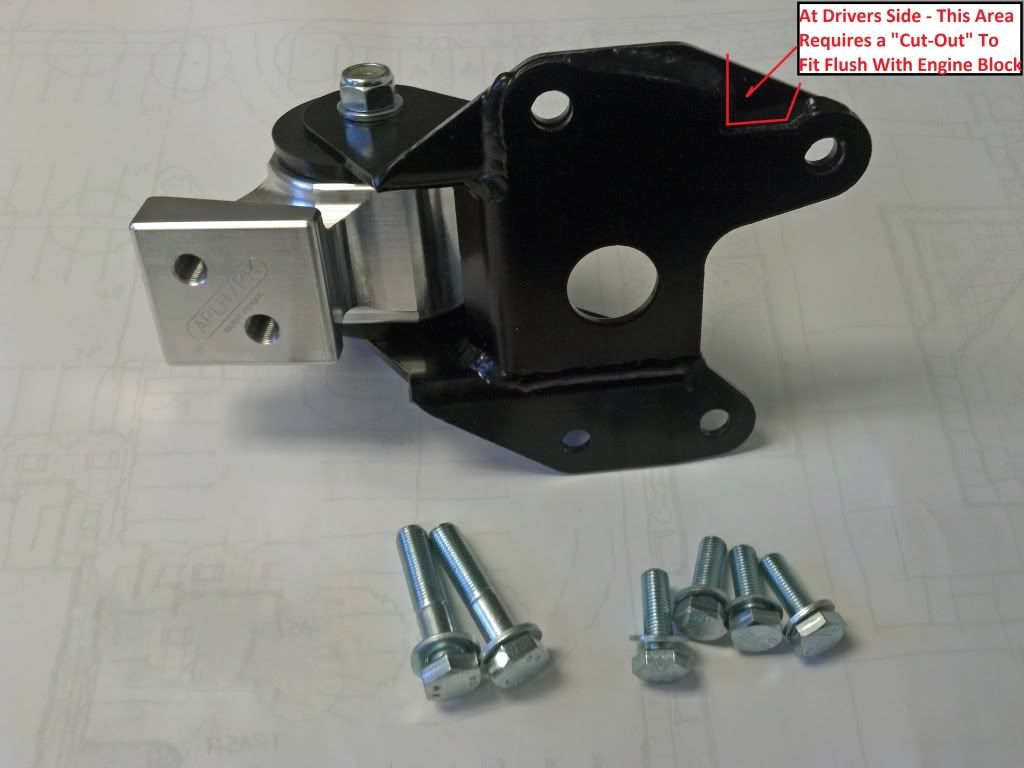

DRIVERS SIDE REPLACEMENT MOTOR MOUNT

I just installed my Drivers Side Hasport Mount about 1/2 hour ago....Here are the pictures.

As we are aware, the Passenger side OEM motor mount gets replaced as part of the PTuning Turbo Kit. Hasport is nice enough to sell you only the needed Drivers Side.

The PTuning Replacement Mount comes with a 60A Hardness.

I ordered the Hasport in the 62A which is a very close match to the PTuning passenger side replacement.

There is almost NO Noticeable Added Vibration....over and above the initial added vibration that was a result of the PTuning Passenger Side Replacement Mount already installed.

Did however have to "Cut-Out" a small piece of the mounting bracket to clear part of the Engine Block. It looks as if the Hasport guys knew this due to one of the plates on the mounting bracket was already "Cut-Out"....but it's like they forgot to finish it off all the way through. (See Picture #1 Below)

All in All...Very Happy So Far..!

I just installed my Drivers Side Hasport Mount about 1/2 hour ago....Here are the pictures.

As we are aware, the Passenger side OEM motor mount gets replaced as part of the PTuning Turbo Kit. Hasport is nice enough to sell you only the needed Drivers Side.

The PTuning Replacement Mount comes with a 60A Hardness.

I ordered the Hasport in the 62A which is a very close match to the PTuning passenger side replacement.

There is almost NO Noticeable Added Vibration....over and above the initial added vibration that was a result of the PTuning Passenger Side Replacement Mount already installed.

Did however have to "Cut-Out" a small piece of the mounting bracket to clear part of the Engine Block. It looks as if the Hasport guys knew this due to one of the plates on the mounting bracket was already "Cut-Out"....but it's like they forgot to finish it off all the way through. (See Picture #1 Below)

All in All...Very Happy So Far..!

#2268

yea i got mine and have to cut a small piece out aswell. not a big deal take less then 10 minutes... the bracket and mount are beefy. and $193 shipped with lifetime warranty, now im just trying find someone to make me a cool box for my filter

#2269

DRIVERS SIDE REPLACEMENT MOTOR MOUNT

I just installed my Drivers Side Hasport Mount about 1/2 hour ago....Here are the pictures.

As we are aware, the Passenger side OEM motor mount gets replaced as part of the PTuning Turbo Kit. Hasport is nice enough to sell you only the needed Drivers Side.

The PTuning Replacement Mount comes with a 60A Hardness.

I ordered the Hasport in the 62A which is a very close match to the PTuning passenger side replacement.

There is almost NO Noticeable Added Vibration....over and above the initial added vibration that was a result of the PTuning Passenger Side Replacement Mount already installed.

Did however have to "Cut-Out" a small piece of the mounting bracket to clear part of the Engine Block. It looks as if the Hasport guys knew this due to one of the plates on the mounting bracket was already "Cut-Out"....but it's like they forgot to finish it off all the way through. (See Picture #1 Below)

All in All...Very Happy So Far..!

I just installed my Drivers Side Hasport Mount about 1/2 hour ago....Here are the pictures.

As we are aware, the Passenger side OEM motor mount gets replaced as part of the PTuning Turbo Kit. Hasport is nice enough to sell you only the needed Drivers Side.

The PTuning Replacement Mount comes with a 60A Hardness.

I ordered the Hasport in the 62A which is a very close match to the PTuning passenger side replacement.

There is almost NO Noticeable Added Vibration....over and above the initial added vibration that was a result of the PTuning Passenger Side Replacement Mount already installed.

Did however have to "Cut-Out" a small piece of the mounting bracket to clear part of the Engine Block. It looks as if the Hasport guys knew this due to one of the plates on the mounting bracket was already "Cut-Out"....but it's like they forgot to finish it off all the way through. (See Picture #1 Below)

All in All...Very Happy So Far..!

Did you repaint the bracket after cutting that small section?

Did you repaint the bracket after cutting that small section?